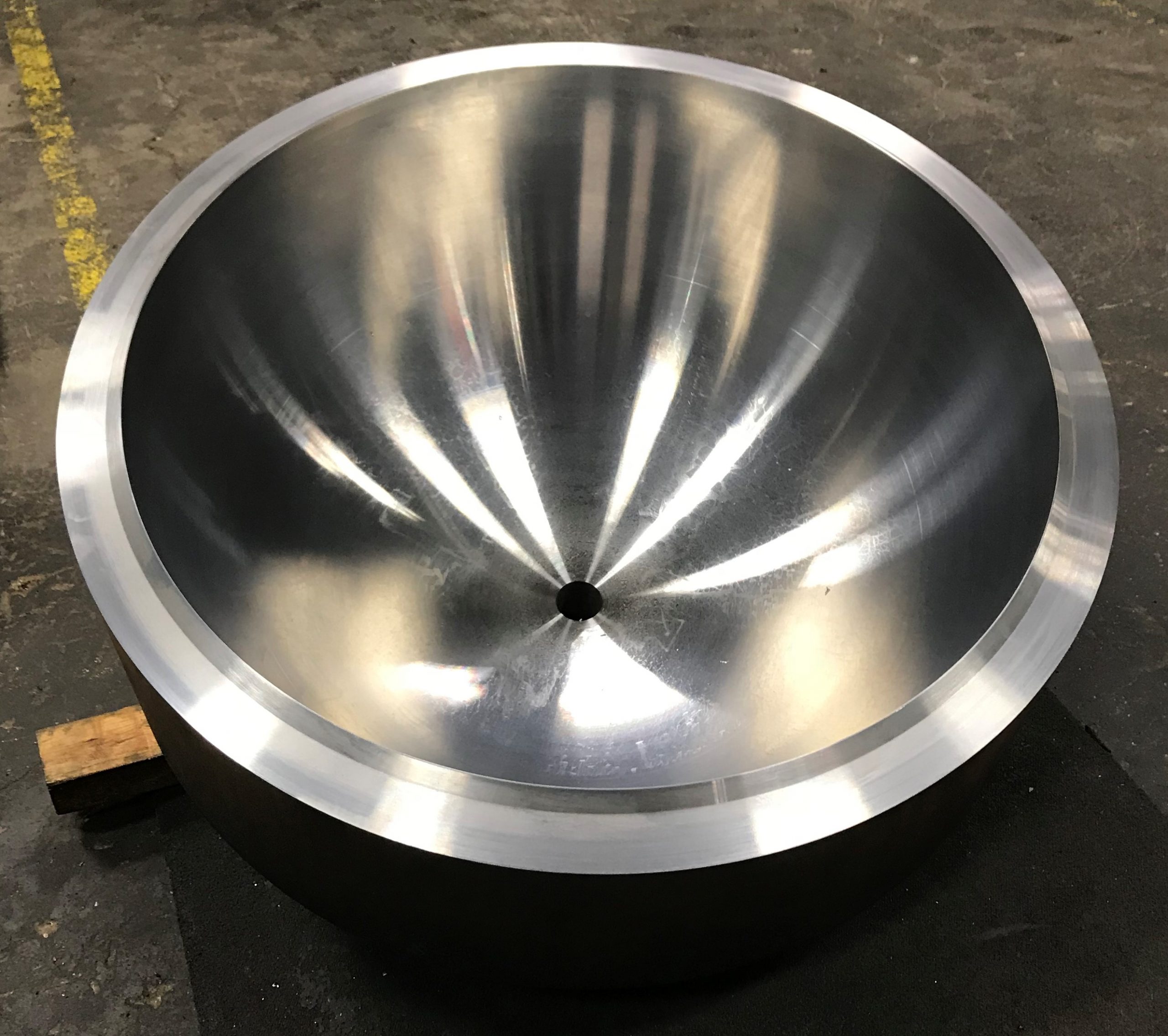

Forged Subsea Products

FCI manufactures raw forgings and finished products for the offshore topsides and subsea applications. Our forgings are made strictly on make to order basis. We have a knowledgeable and experienced personnel with offshore and subsea experience, as well as engineering and design capabilities to manufacture products to meet customer functional requirements. We also stock a large amount of offshore applicable material grades that meet some of the more challenging end user material demands.

All the manufacturing processes are completed strictly in-house, allowing us the most flexibility and efficiency when it comes to completing any customer order. Starting with a strategic and metallurgical approach to raw material selection to forging, heat treating, machining and NDE; we ensure the finished product meets the highest quality.

Forged offshore topside and subsea products are specialized components made through the forging process, which involves shaping metal under high pressure without melting it. These products are essential in the construction and maintenance of offshore structures, particularly in the oil and gas industry.

Types of Subsea Products

Forged Offshore Topside Products

Valves and Blocks: Forged steel valves and blocks are used in topside facilities to control the flow of oil, gas, and water. These are critical for safety and operational efficiency.

Flanges: These are used to connect pipes, valves, pumps, and other equipment. Forged flanges are preferred for their strength and resistance to fatigue and corrosion.

Manifolds: Manifolds distribute or collect fluids from multiple sources. Forged manifolds are used for their durability and resistance to high pressures.

Pressure Vessels: Pressure vessels hold gases or liquids at a pressure different from the ambient conditions. Forging ensures their robustness and leak-proof properties.

Forged Subsea Products

Subsea Trees: These are assemblies of valves and other components used to control the production of a subsea well. Forging gives them the necessary strength to withstand harsh subsea environments.

Connectors and Hubs: These components are used to connect various subsea equipment. They need to be extremely reliable and durable, making forging an ideal manufacturing process.

Shafts and Gears: Forged shafts and gears are parts of subsea machinery that require high precision and strength to function effectively under the ocean.

Piping Systems: Subsea pipelines that transport oil and gas from the wellhead to the surface or across the sea floor are often connected using forged fittings to ensure tight and secure connections.

Subsea Applications

Oil and Gas Extraction: Both topside and subsea forged products are critical in the setup and operation of offshore drilling rigs and platforms.

Underwater Mining: Subsea forging products are also used in the mining industry to handle the tough conditions found on the seabed.

Renewable Energy: In offshore wind farms, forged components are used in the construction of wind turbine columns and anchors.

Marine Engineering: Forged products are utilized in the construction of ships, especially those designed for heavy-duty or specialized tasks.

These forged products are favored for their superior strength, fatigue resistance, and ability to handle extreme pressures and corrosive environments, which are common in offshore and subsea operations. Their production involves sophisticated techniques and high-grade materials to ensure safety, durability, and effectiveness in critical applications.