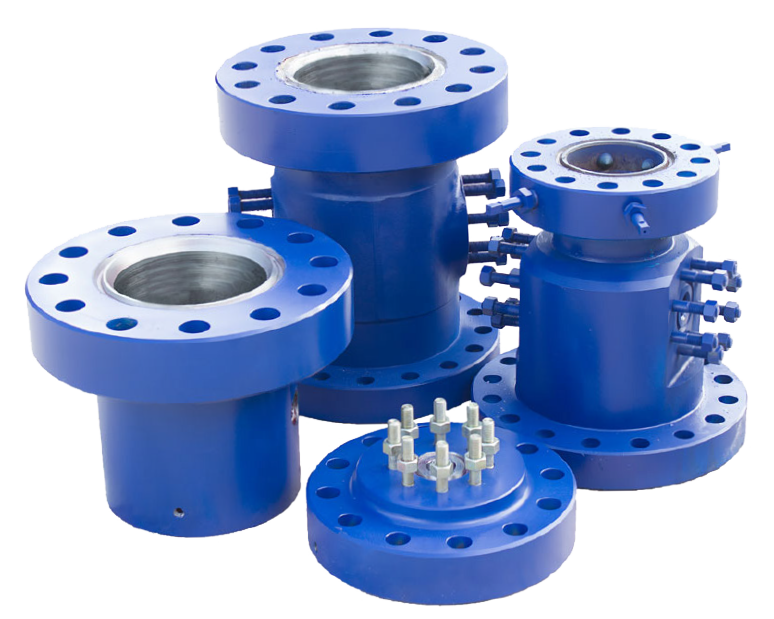

Forged Wellhead Casings

Wellhead casings are integral components in the drilling and production of oil and gas wells. These steel pipes are installed in drilled holes and cemented in place to stabilize the wellbore, control pressure, and protect groundwater by preventing contamination. The casing serves as the foundation for the well, ensuring structural integrity and safety throughout the drilling and production processes. Different sections of the well are typically lined with various types of casing strings, including conductor casing, surface casing, intermediate casing, production casing, and liner strings, each serving specific functions at different depths.

Structural Support

One of the primary functions of wellhead casings is to provide structural support to the wellbore. As drilling progresses deeper into the earth, the surrounding geological formations exert pressure on the wellbore, which can cause it to collapse without proper support. The casing prevents this by reinforcing the wellbore walls, maintaining the well’s integrity, and enabling further drilling and production activities. This support is crucial in both onshore and offshore drilling operations, where maintaining a stable wellbore is essential for safety and operational efficiency.

Pressure Control

Wellhead casings play a critical role in controlling the pressure within a well. During drilling, the pressure from underground formations can be highly variable and sometimes extreme. Proper casing installation helps manage these pressures, preventing blowouts and ensuring that drilling operations can be conducted safely. The casing also serves as a barrier, isolating high-pressure zones from other parts of the well, which is essential for preventing cross-flow of fluids between different geological formations. This isolation is crucial for maintaining well control and protecting the integrity of the well throughout its lifecycle.

Environmental Protection

Environmental protection is another significant application of wellhead casings. By cementing the casing in place, operators can effectively seal off the wellbore from surrounding roundwater sources, preventing contamination from drilling fluids and hydrocarbons. This sealing process ensures that potentially harmful substances do not migrate into freshwater aquifers, protecting the environment and adhering to regulatory requirements. Moreover, the casing prevents the ingress of external fluids into the well, which can compromise the quality of the produced hydrocarbons and affect the overall efficiency of the well.

Enhanced Production Efficiency

In the production phase, wellhead casings are essential for maximizing the efficiency and safety of hydrocarbon extraction. The production casing, specifically, provides a conduit through which oil and gas can be safely and efficiently transported from the reservoir to the surface. By maintaining the integrity of the wellbore and ensuring proper pressure control, the casing helps optimize production rates and prolong the life of the well. Additionally, wellhead casings enable the implementation of enhanced recovery techniques, such as hydraulic fracturing, by providing a stable structure that can withstand the pressures and stresses involved in these processes.

We handle all manufacturing processes in-house to ensure maximum flexibility and efficiency when fulfilling customer orders. Beginning with careful raw material selection, we follow a strategic and metallurgical approach through forging, heat treating, machining, and final inspection (FCI) to guarantee the highest quality standards and on-time delivery of our finished products.