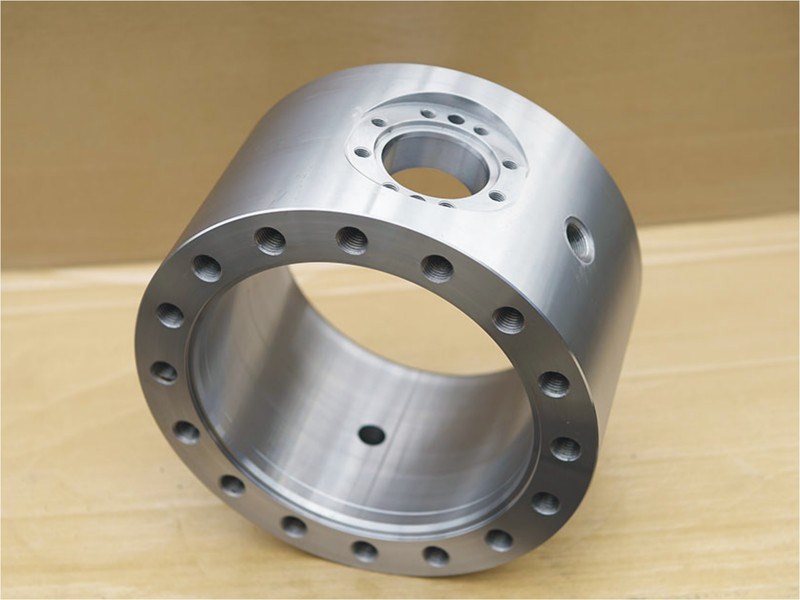

Forged Valve Bodies

The process of making forged valve bodies involves heating and shaping solid steel using a die forging machine. The metal is compressed, bent, and molded to match the desired valve design.

Forged valves are produced by shaping metals and alloys in their solid state. Heat and industrial tools apply compressive forces to bend the materials, while dies are used to cut and shape them into specific valve designs.

Typically, forged valves are preferred for high-pressure and high-temperature situations due to their durability and reliability. However, casting valves may be more suitable for low-pressure scenarios or when a large quantity of valves is required, considering cost and production convenience.

The use of the forging process in manufacturing high-performance ball valves offers several advantages over alternative methods. These valves are less prone to problems like cracking, porosity, and shrinkage, making them more durable and reliable.

Additionally, forged valves are better equipped to handle temperature fluctuations, making them a low-maintenance option. Consequently, they are preferred in industries such as Liquified Natural Gas (LNG) and Compressed Natural Gas (CNG) due to their exceptional qualities.

We offer valve design and manufacturing services and are proud to manufacture all our products in the U.S.A. for quality control. Contact us today with your valve requirements or other forging needs.