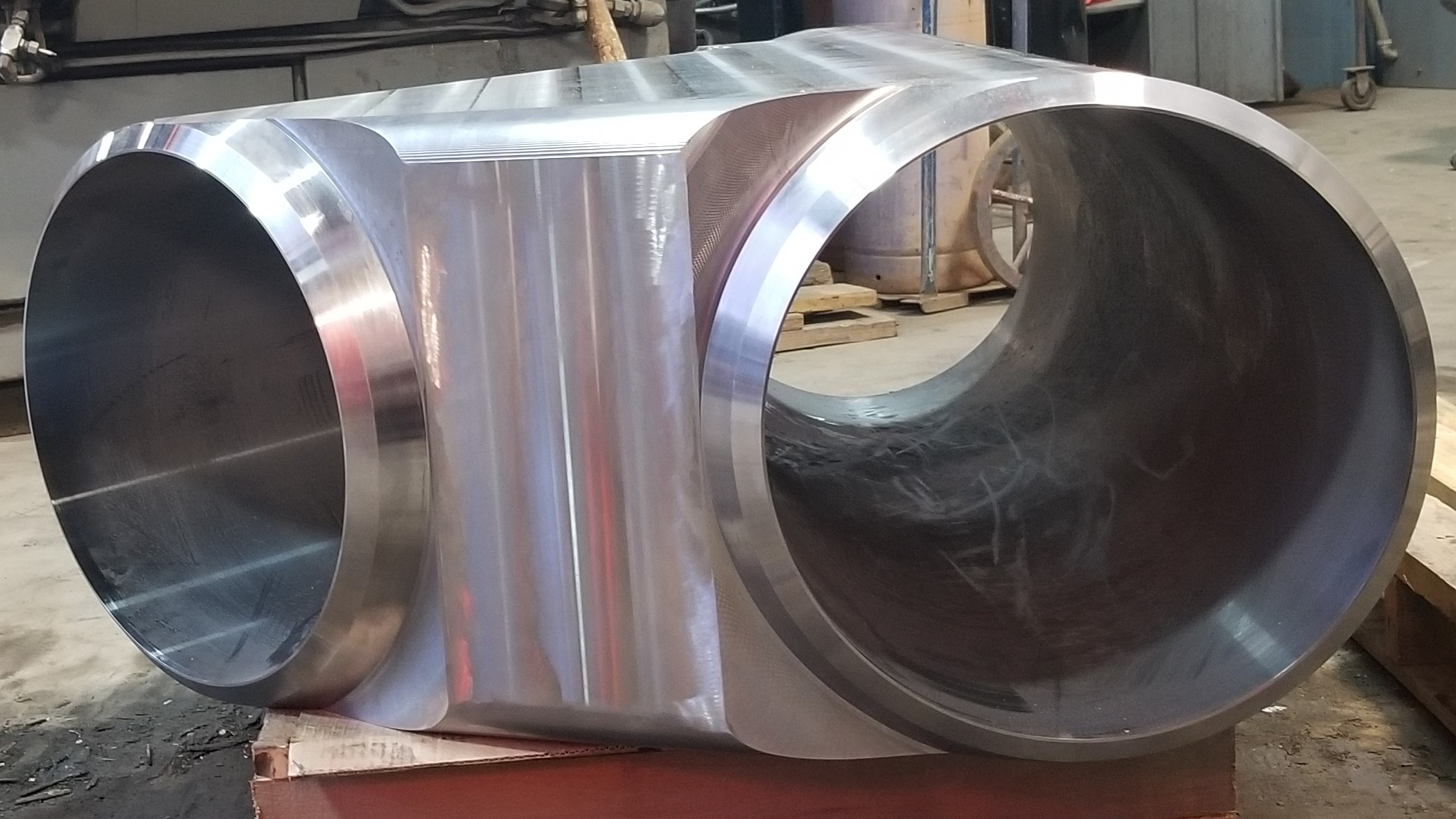

forged laterals

Forged lateral tees are specialized pipe fittings used in piping systems, particularly in the oil, petrochemical, and gas industries. Unlike regular tees, which have branches at a 90-degree angle from the main pipe, lateral tees have branches that extend at a 45-degree angle. This unique design allows for smoother flow transitions and reduces turbulence, making them ideal for certain applications where flow direction changes are required without significantly impacting the flow dynamics.

Descriptions & Types

Equal Lateral Tees: These fittings have the branch and the main pipe of the same diameter, facilitating a uniform flow rate throughout the system.

Reducing Lateral Tees: These are used to connect pipes of different sizes. The branch of the tee is smaller than the main pipe, allowing for the integration of different-sized pipes within the system.

Materials:

Flow Direction Changes: Forged lateral tees are used when the flow direction needs to be changed smoothly without causing significant pressure drops or flow disturbances. The 45-degree angle helps in minimizing flow resistance when diverting the flow.

Integration of Auxiliary Equipment: In processing plants, lateral tees are often used to integrate auxiliary equipment or instrumentation into the main flow line without significantly disrupting the flow.

Space Constraints: The angled branch of a lateral tee can offer a solution in tight spaces where a standard tee cannot be accommodated due to space limitations.

High-Pressure Systems: The forging process enhances the strength and durability of lateral tees, making them suitable for high-pressure applications common in the oil, gas, and petrochemical industries.

Corrosive Environments: The materials used in forged lateral tees can be selected for their corrosion resistance to withstand the harsh chemicals and environments encountered in these industries.

Efficiency and Safety: The use of lateral tees can contribute to the overall efficiency and safety of piping systems by ensuring smooth flow transitions, reducing the risk of flow-induced vibration, and minimizing the potential for leaks at connection points.

Like other forged fittings, lateral tees are made from various materials such as carbon steel, stainless steel, and alloy steel. The choice of material depends on the application requirements, including temperature, pressure, and the presence of corrosive substances.