Non-Destructive Examination

What is Non-Destructive Examination

Non-Destructive Examination (NDE) is a set of processes used to evaluate the properties of forged components without causing any material damage. NDE is particularly important for forged flanges and pressure vessels to ensure their integrity, reliability, and safety. Our NDE inspection may include:

Ultrasonic Testing (UT)

Ultrasonic testing uses high-frequency sound waves to detect internal and surface defects. A transducer sends sound waves into the material, and the reflections from defects are recorded and analyzed.

- Applications: Detecting internal flaws, measuring thickness, and assessing weld quality.

- Advantages: Can detect subsurface defects; highly accurate.

- Limitations: Requires skilled operators and calibration; difficult on rough or irregular surfaces.

Magnetic Particle Testing (MT)

Magnetic particle testing can detect surface and near-surface defects in ferromagnetic materials. The component is magnetized, and iron particles are applied to the surface. Defects cause a leakage field that attracts the particles, making the defect visible.

- Applications: Detecting surface cracks, seams, and inclusions.

- Advantages: Quick and cost-effective; can detect very fine defects.

- Limitations: Only applicable to ferromagnetic materials; limited to surface and near-surface defects.

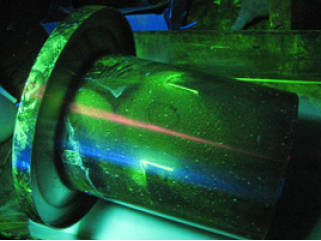

Dye Penetrant Testing (PT)

Dye penetrant testing involves applying a liquid dye to the surface of the component. The dye penetrates surface-breaking defects, and after removing the excess dye, a developer is applied to draw the dye out, revealing the defects.

- Applications: Detecting surface cracks, porosity, and other discontinuities.

- Advantages: Simple and inexpensive; highly sensitive to surface defects.

- Limitations: Limited to surface defects; requires clean and dry surfaces.

Magnetic Particle Testing (MT)

Magnetic Particle Inspection (MPI), is used to detect surface and near-surface defects in ferromagnetic materials. It is commonly used to identify cracks, seams, and other discontinuities that may not be visible to the naked eye.

- Magnetization: The component to be tested is magnetized using either a direct or indirect magnetization method.

- Application of Magnetic Particles: After magnetization, fine magnetic particles, either dry powder or suspended in a liquid carrier, are applied to the surface of the component.

- Formation of Indications: When the magnetic field encounters a discontinuity (such as a crack), it creates a leakage field at the defect.

- Inspection: The inspector examines the component under appropriate lighting conditions to identify any accumulations of magnetic particles, which indicate the presence of defects.

- Demagnetization and Cleaning: After inspection, the component is demagnetized to remove any residual magnetism and cleaned to remove any remaining magnetic particles.

Importance of NDE in Forged Flanges and Pressure Vessels

- Safety: Ensures the structural integrity of components that operate under high pressure and temperature, preventing catastrophic failures.

- Quality Assurance: Verifies that the components meet industry standards and specifications.

- Cost Efficiency: Identifies defects early in the manufacturing process, reducing the cost of repairs and downtime.

- Regulatory Compliance: Helps manufacturers comply with industry regulations and standards, such as ASME and ASTM.

Why Do We Perform the Non-Destructive Examination?

This inspection is mainly done for the purpose of quality control. It helps in determining the defects in forged flanges products and also the quality of raw materials that are used to manufacture it. Non-destructive examination can also help in determining design faults or flaws in a product before it is mass produced.

Offering top quality services for forged flanges across different industries, including Oil & Gas, and Petrochemical, FCI can be your go-to company for the best NDE services.