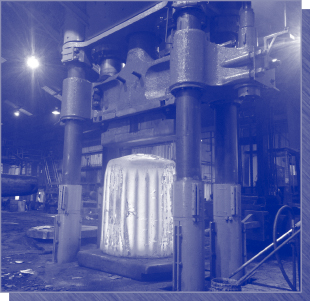

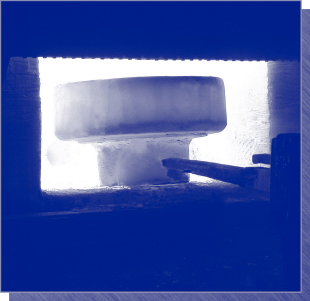

FORGE MANUFACTURING CAPABILITIES

Forged Components provides a variety of capabilities to meet the diverse needs of its clients, primarily in industries like oil and gas, petrochemicals, and water treatment. Here is an overview of our manufacturing capabilities:

Material Diversity: We have the experience and machinery to work with a wide range of materials including carbon steel, stainless steel, alloy steel, and exotic materials like Inconel, Monel, and titanium. This ensures that flanges and pressure vessels can be manufactured to suit specific environments and pressures.

Custom Manufacturing: Our facilities offer custom flange solutions tailored to our client specifications, including size, shape, and material. This includes producing flanges based on detailed engineering drawings and specific industry standards.

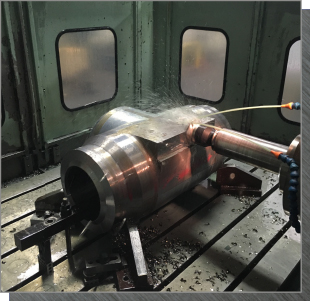

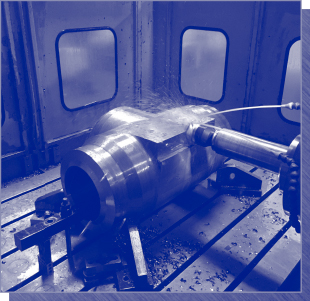

Machining Capabilities: Our high precision machining facilities capable of achieving tight tolerances required for flange interfaces. This includes CNC machining, drilling, and finishing services.

Testing and Quality Assurance: Comprehensive testing capabilities to ensure product integrity and compliance with industry standards. This includes non-destructive testing (NDT) methods such as ultrasonic testing, magnetic particle inspection, and X-ray testing, as well as mechanical testing for tensile strength, hardness, and impact resistance.

Certification and Standards Compliance: Our manufacturing process adheres to international and national standards such as ANSI, ASME, ISO, and API. This ensures our forged products are certified and meets rigorous industry requirements.

Supply Chain and Inventory Management: We have the ability to manage a reliable supply chain and maintain a stock of standard flanges to ensure quick delivery times while efficiently handling logistics and export protocols.

Technical Support and Customer Service: We deliver industry leading technical support during the selection and design phases, as well as after-sales support. This includes consultation on the best materials and designs for specific applications.

Environmental and Safety Standards Compliance: Adherence to environmental regulations and safety standards in the manufacturing process to ensure sustainability and safety at the workplace.

Having all of these capabilities and team experience ensures that as a forge flange and pressure vessel components manufacturer, we can deliver high-quality products tailored to meet the specific needs of various industries, while also adhering to safety, quality, and regulatory standards.