FCI Studding Outlet Manufacturing Standards

There are standards or requirements that must be adhered to during the studding outlet manufacturing process.

Below are the general standards of the FCI studded outlets:

The codes, materials, and bores

First and foremost we have ensured that all our outlets are manufactured according to the ASME specifications including the:

« Section II

« Section VII

« Div I

« ASME B16.5

There are other special requirements including; the section I, III and VIII, Div 2, ASME B31.1 or the B31.7 that can be produced.

Our materials too have been made according to the ASTM and the ASME specifications. The standard material that is used is carbon steel SA105. Upon request, we can make connections in other materials including; stainless steel, alloy steel, carbon steel, non-ferrous alloy and the high nickel.

When it comes to the bores, they have been made equal in size with the pipe or the normal flange. You may, however, still request for special bores if you need them.

The facing

The facings differ depending on the type of studded outlets however the standard face of an outlet is ASME B16.5. For studded outlets class 150 and 300, the face is raised with 0.06 and 0.25 in class 600, 900, 1500 and 2500.

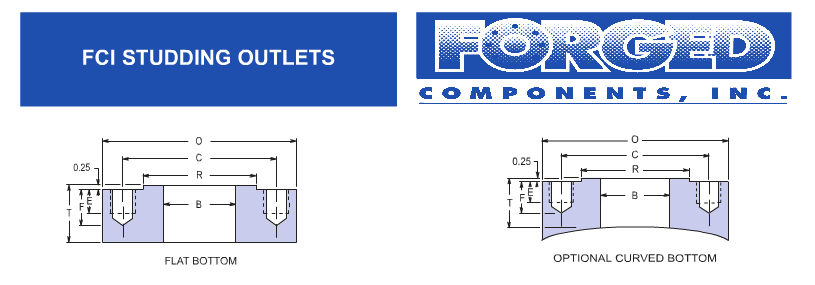

The studded outlet’s thickness, body, and the bottom

The minimum thickness required is listed on our FCI charts, and they are done according to the ASME Section VIII Div 1.

The body, on the other hand, has been designed as required by the ASME B16.5. The studded outlet’s diameters and the flanges are equal. They can be increased though upon request.

The studded outlet’s bottoms are flat unless required otherwise.

We divulge more information when you come in for a consultation. If you have any questions, you can contact us, and we will be happy to help.