Forged Components vs. Cast Components – Which is Better?

The short answer is that it depends on what you are using the components for. Forged components and cast components are similar in several ways.

- Both require the steel to be heated at high temperatures until it becomes malleable

- Both can have surface finish treatments applied, such as painting, powder coating, polishing, etc.

- Both components may be altered in some way through assembly, welding, brazing, etc.

What Are Forged Components?

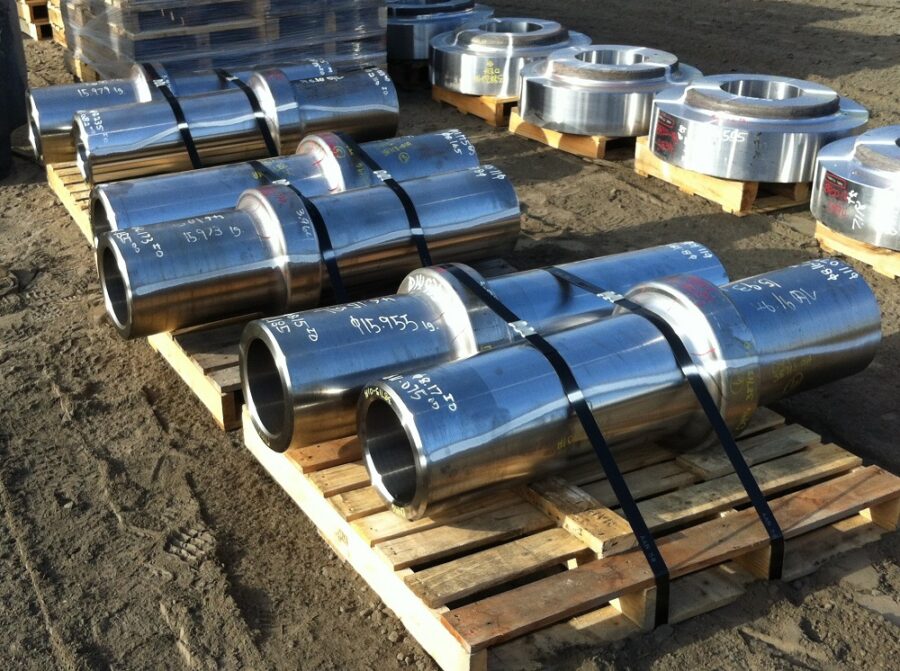

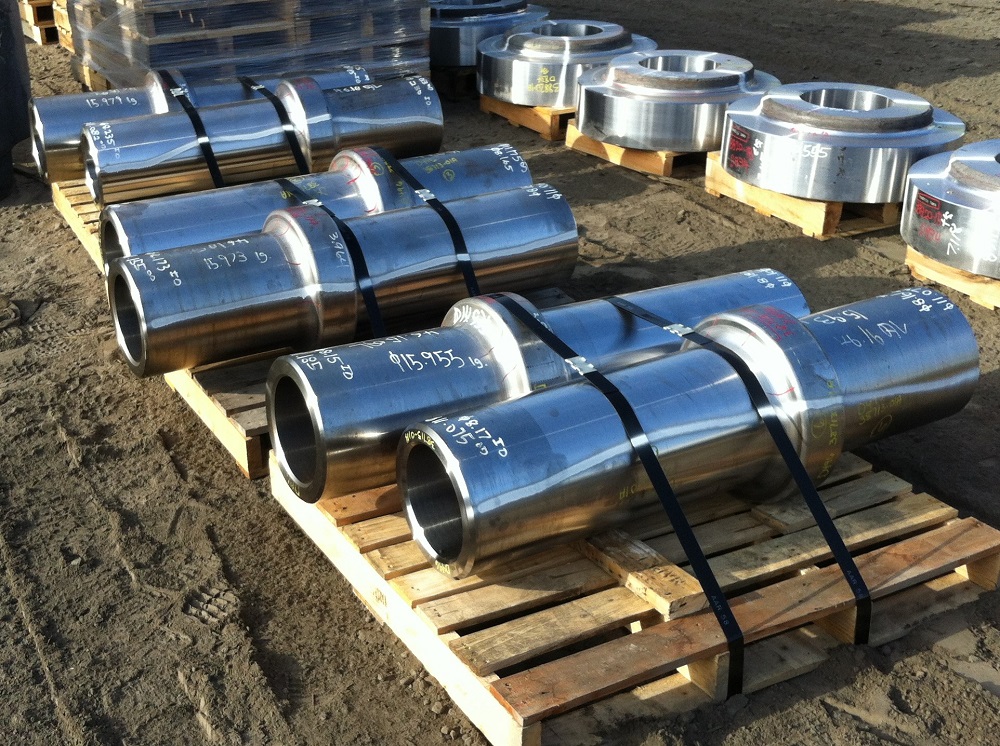

Forged components are parts made of steel that has been heated and hammered into specific shapes which realign the metal grains so that the metal becomes much stronger, harder, and more wear-resistant than its cast component counterparts. Here are some of the other reasons forged components are better than cast components:

- Forgings also respond to heat treatment better than castings

- Forgings can withstand more substantial impacts and mechanical force

- Forgings work better in parts that are subject to high loads and stress

- Forgings limit the formation of cavities, pockets, and gas void areas

What Are Cast Components?

Cast components are parts created by super-heating the steel until it becomes liquid and then pouring it into a mold in the shape of the part to be created. There are two types of casting—sand casting, where the molten steel is poured into a shape pressed into special clay or sand and primarily used for casting large parts, and investment casting, where the molten steel is injected into a metal die and ceramic coating and mainly used for more delicate and detailed part shapes. Here are some of the reasons you would select cast components over forged components:

- Castings work better for parts with internal cavities

- Castings can use special alloys—such as those using high amounts of moly or nickel, which are harder to forge

- Castings can produce extremely large-sized parts, where forged parts are limited by the size of the available forging equipment

- Castings are better for mass-produced parts

- Castings cost a lot less than forgings

For these reasons, forged components are more common in industries where strength, wear resistance, and hardness are extremely important to prevent failure, leading to dangerous, even disastrous results. Industries such as oil and gas production, petrochemical processes, heavy truck and automobile parts, medical parts, and aerospace components use many forged components.

Forged Components Is One of the Premier Custom Forging Manufacturers in the World

Forged Components manufactures custom forgings for use across the spectrum of the energy production process. From oil exploration to petrochemical production and delivery, FCI manufactures various forged components used in all of these processes. We complete all manufacturing processes in-house so that we have maximum flexibility and efficiency when filling your order. For more information, call us at (281) 441-4088 or contact us online to get a quote from our sales staff.