More Common Valves Used in the Oil & Gas Industry

Last month we discussed some of the common valves used in the oil and gas and petrochemical industries. But there are many different types of valves used as pressure vessel connections for oil, gas and petrochemical tasks. Here are a few more valve types you should be aware of:

ARC Valves

Also known as ARV (Automatic Recirculation Valves), ARC (Automatic Recirculation Control) valves, are specifically designed to protect centrifugal pumps from overheating. They do this by assuring that a specific minimum flow is pushed through the centrifugal pump at all times. This minimum flow is essential for these pumps because a dry valve leads to overheating which can cause permanent damage to the pump if the flow issue is not immediately addressed.

Breather Valves

Typically, breather valves protect the nozzle openings on top of bulk storage tanks. Also known as vacuum relief valves, these valves prevent the buildup of a vacuum or excess pressure which might unbalance the system as a whole or damage the pressure vessel through an implosion–if an activity in the piping system reduces the pressure in the tank below that of the outside atmospheric pressure–or a rupture–if the tank pressure exceeds the pressure vessel’s design through the pumping of liquid or vapor into the tank.

This valve must be used in accordance with the American Petroleum Institute’s API standard 2000 for venting atmospheric and low-pressure storage tanks.

Control Valves

Control valves are valves that use a controller to provide management of the flow rate within a piping system and, as a result, control the pressure, temperature and fluid level within that system. These valves can be operated remotely and work with hydraulic, pneumatic, or electrical signals sent from a controller.

Pinch Valves

Pinch valves use elastic tubing to throttle and shut off pipes that move thick fluids (such as slurries) or solid particles such as powders or pellets. They are often used in situations where abrasion from the flowing media is a problem.

Piston Valves

Piston valves use a piston to help turn on or off the flow of gas, steam or other fluids in a piping system. It is a low maintenance valve that can be manual or part of an electric or hydraulic system.<

Plug Valves

A plug valve uses a roughly cylindrical shaped plug to stop or start a flow with a simple quarter turn. They can have two or three ports, which can determine where the fluid flows within a piping system, either moving the fluid from one port to another, or mixing fluids from all three ports.

Safety Valves

A safety valve is exactly what it sounds like–a valve used in a series of high-pressure pipes designed to release pressure if the pressure reaches a dangerous level. Without safety valves, the system may exceed the pipe’s pressure capacity and rupture endangering both property and people near the pipe.

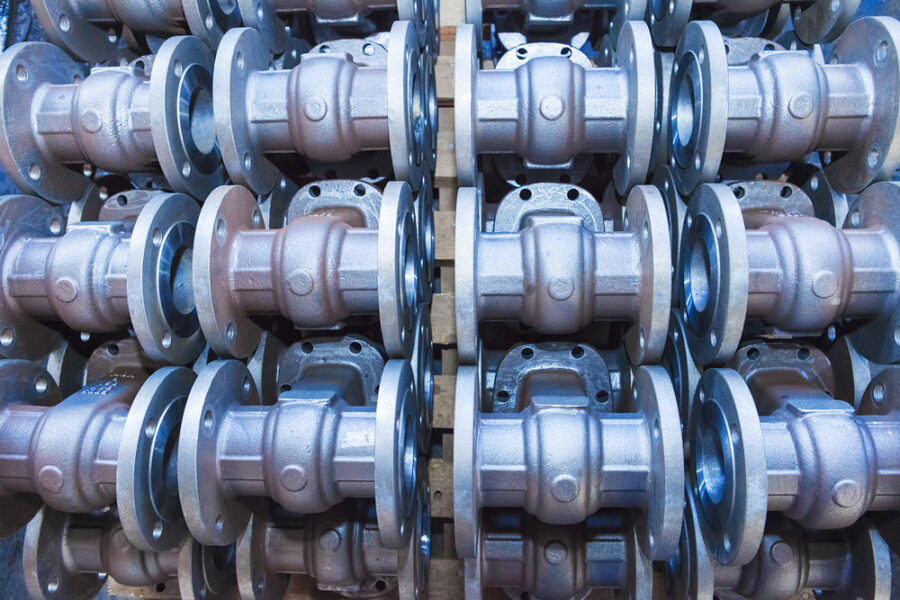

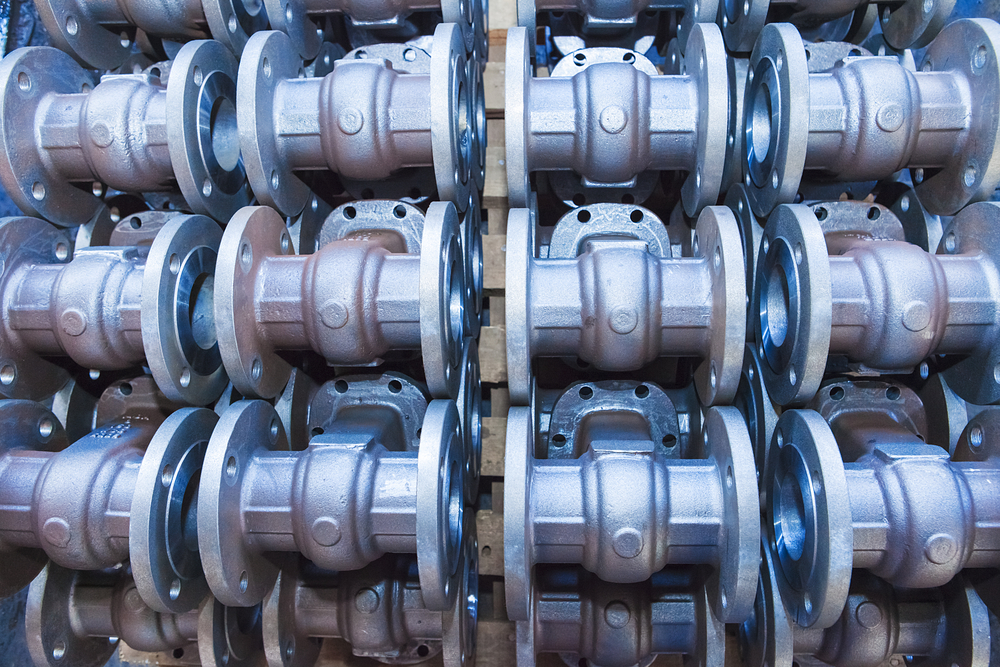

Looking for a Manufacturer of Forged Valve Components?

Forged Components Inc. (FCI) manufactures forged valve components for a variety of commonly used valves in the oil & gas and petrochemical industries. FCI specializes in forging valve bodies and adapters from a wide range of material grades that it carries in its vast raw material inventory. They can deliver such components in a very timely manner for different industry applications. For more information, please give us a call (281) 441-4088 or contact us online to speak to one of our sales staff.