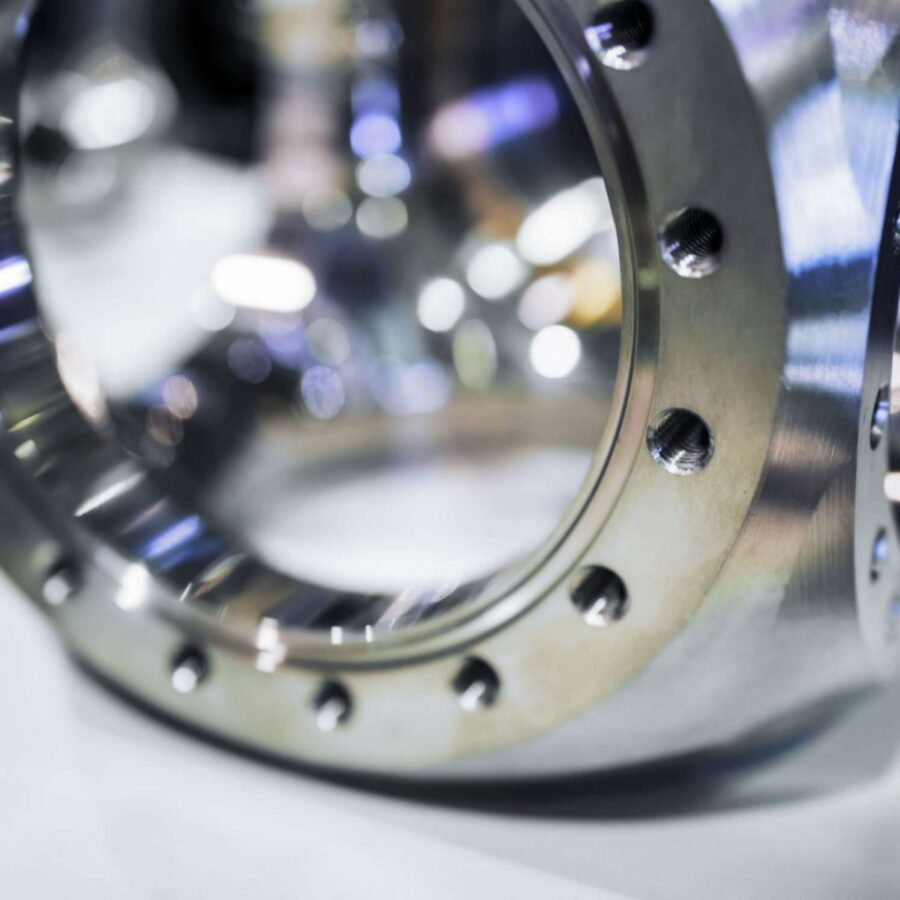

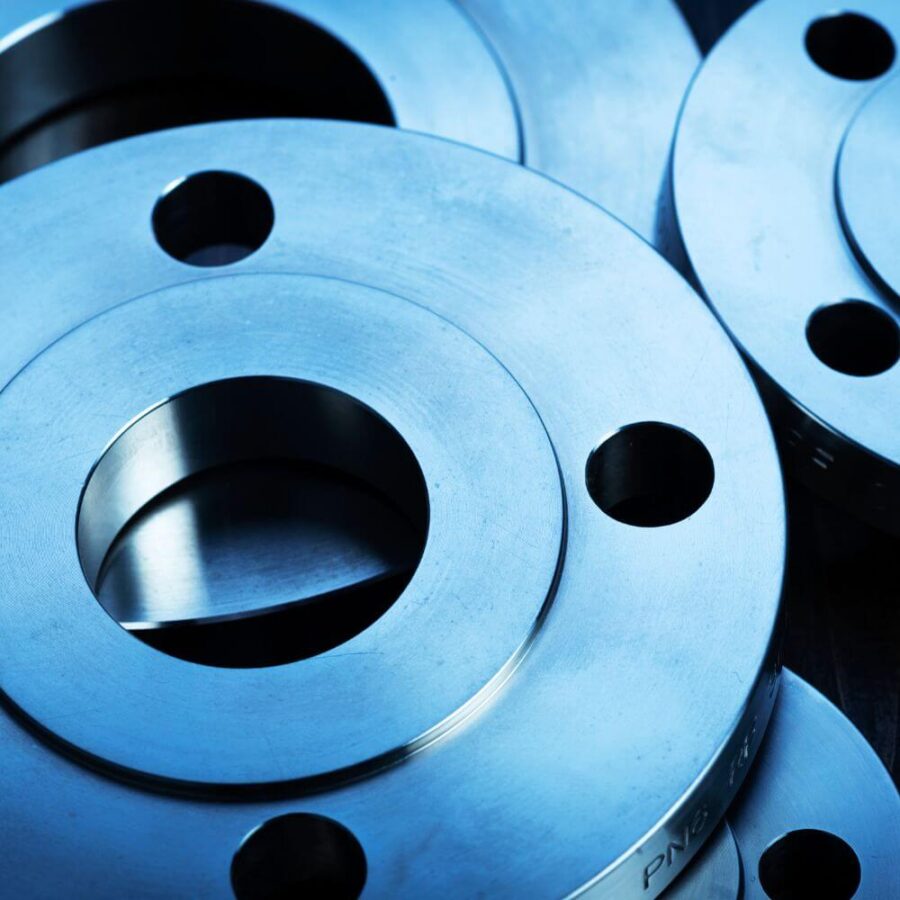

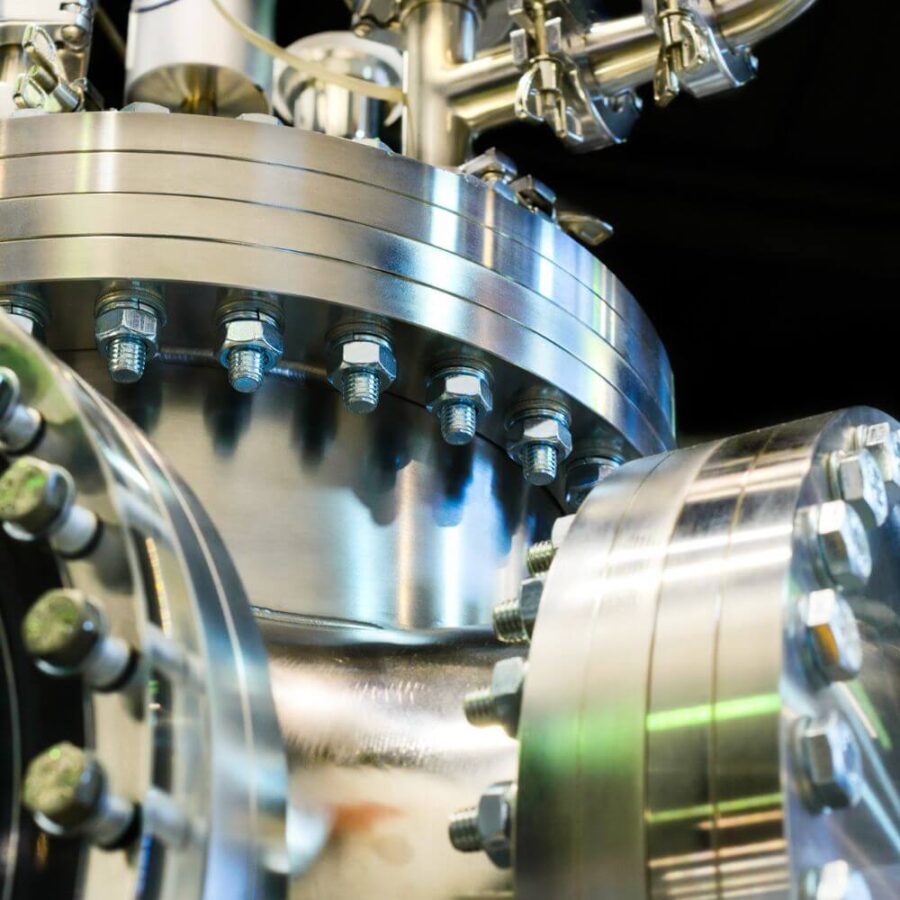

Forged Components Seamless Pressure Vessel Connections Improve Safety

The evolution of pressure vessels has come a long way since their inception during the industrial revolution. Initially used to generate steam for trains and steamboats, pressure vessels were designed with safety in mind, both for the engines they powered and the operators who ran them. Over the years, pressure vessel connection manufacturers have improved their designs, keeping up with …