What Components are Used in a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger is a pressure vessel connection named after two of its major parts. The tubes mounted inside of a cylindrical shell which is used to exchange heat in oil production and chemical processes. Most shell and tube heat exchangers are constructed of various grades of carbon steel but can be made of many different metals and alloys including copper, copper-nickel, stainless steel, and titanium (just to name a few). The shell and tube heat exchanger is the most common heat exchanger design used in industrial processes because they are more sturdy than other designs and can handle a lot of physical punishment and stand up to the most caustic processes.

Shell

The shell is a cylinder that either is fabricated from a rolled plate metal sheet or from an appropriately sized pipe (up to 24 inches in diameter). Most of the time, this metal is steel, but other metals and alloys might be necessary if the shell is exposed to high temperatures or corrosive agents. The shell also incorporates a nozzle inlet and incorporates an impingement plate if the fluid velocity is high in order to distribute that fluid evenly in the tubes as it flows into the heat exchanger.

Tubes

These tubes can be drawn from the metal creating seamless tubes or can be fabricated from sheets of metal by rolling them into a tube shape and welded. Most tubes used in shell and tube heat exchangers are between 5/8 inch to 1 inch, although other sizes are sometimes used depending on the particular situation. Some tubes might include fins in order to help expand the heat transfer surface area between the tubes and the surrounding fluid. These fins might be longitudinal fins that run the length of the outside of the tube or transverse fins which are hollow metal discs encircling the outside of the tube that are evenly spaced from each other along the length of the tube.

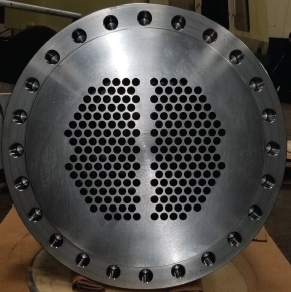

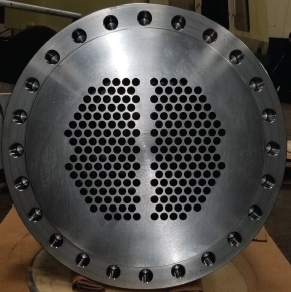

Tube Sheets

The tube sheets are the forged plates that have precise holes drilled through them for the tubes to be inserted and then welded in place. For more details about the function and roles of a tube sheet in a shell and tube heat exchanger, check out our blog post What is a Tube Sheet for a Heat Exchanger?

Baffles

Baffles guide the tubes during the assembly process of a shell and tube heat exchanger and they support the tubes, prevent vibration, maintain the spacing between the tube inserted through the tube sheets, and direct the flow of fluid through the shell.

Rods and Spacers

Rods and spacers hold the baffles together and maintain the spacing between them as the heat exchanger has designed. The number of rods and spacers used within the exchanger depends upon how many baffles are used and the diameter of the overall shell.

Channels

Channels (AKA Heads) contain the fluid for the tube side and determine the flow path through the shell and tube heat exchanger. There is a front channel and a rear channel for each exchanger. There are many designs for these channels based on how you want the fluid to enter the heat exchanger (through the front channel) and how you want it to leave the heat exchanger (through the rear channel).

FCI Manufactures Forged Tube Sheets and Other Custom API & ASME Pressure Vessel Connections

Forged Components Inc. (FCI) is the leading ASME pressure vessel connections manufacturer that also specializes in the production of forged tube sheets for various heat exchanger fabricators throughout North America. For more information, please call us at (281) 441-4088 or contact us online to get a quote from our sales staff.