What is a Natural Gas Compressor Station?

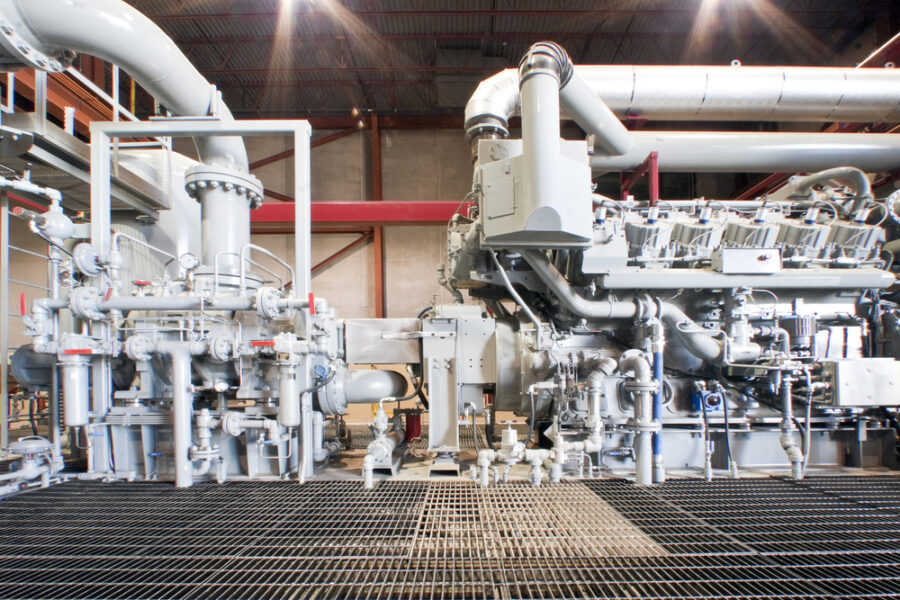

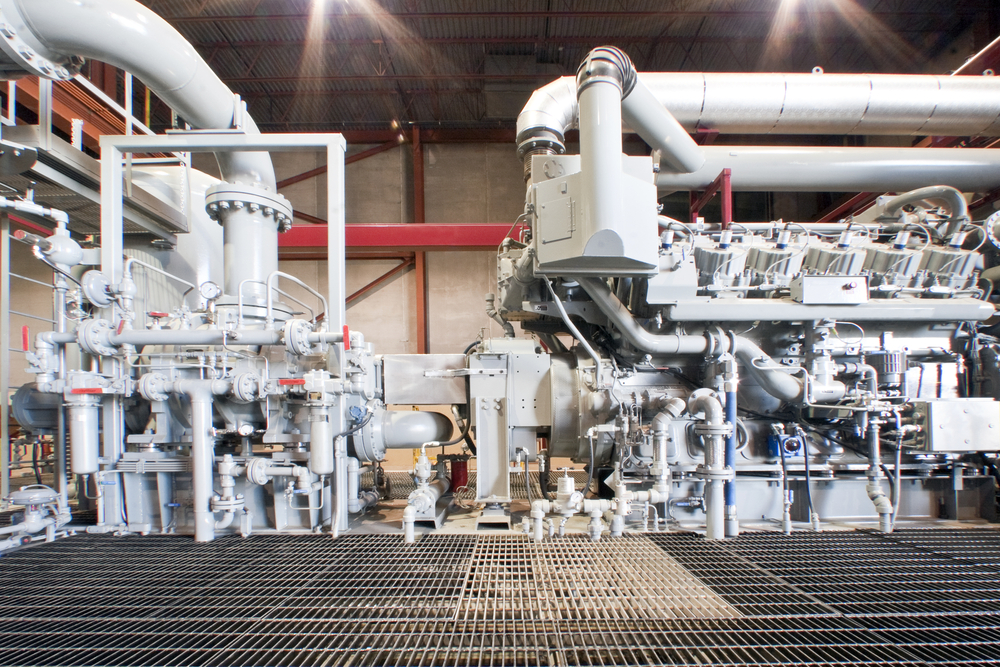

A natural gas compressor station is a part of a network of pipes, connectors and flanges designed to transport gas from the production wells to the gas consumers. Because of factors such as the distance between the well and end-user, friction, and different elevation along the pipeline, the gas needs a periodic “boost” along the natural gas pipeline network to help maintain a consistent pressure and flow during the transport.

These compressor stations might be housed in buildings, or just out in the open. How the compressor stations are designed depend on the needs in a particular area of the country. For example, some compressor stations are located in environmentally-sensitive areas or near highly-regulated areas where people live and work. These compressor stations tend to be housed in buildings in order to provide security, reduce noise, and make maintenance on the compressor station easier.

The Natural Gas Compression Process

The gas enters the compressor station through a series of pipes that connect from the main gas pipeline named yard piping. The yard piping moves the gas through a series of filters and scrubbers which remove any liquid or solid contaminants within the gas stream. It then re-enters the compression station yard piping and into a compressor unit. The compressor re-pressurizes the gas, so it will flow consistently through the main natural gas pipeline network, but when increasing the pressure of the gas it also generates heat which must be managed. To solve this problem, the compressor station has a cooling system designed to dissipate the added heat, usually by using a series of fans to help cool the pipes as they radiate the heat away. This cooling process–including the changes in pressure and temperature–causes some of the liquid in the gas to condense and drop out of the main gas flow.

Other Functions of a Natural Gas Compressor Station

Once the gas has been repressured, other processes such as adding mercaptan, the sulfurous odor that indicates the presence of natural gas, might be part of the process at the gas compressor station.

Other features of a typical gas compressor station include extensive system monitoring, gas pressure monitoring and safety control equipment. Backup generators, in case of an interruption in power, are also a key component to help keep the natural gas pipeline flowing consistently and evenly.

Need Flanges, Nozzles or Other Pressure Vessel Components for Your Compressor Station?

Let Forged Components supply them for you. We provide a complete line of industrial forged flanges and nozzles for the oil, gas and petrochemical industries. For more information, call us at (281) 441-4088 or contact us online to get a quote from our sales staff.