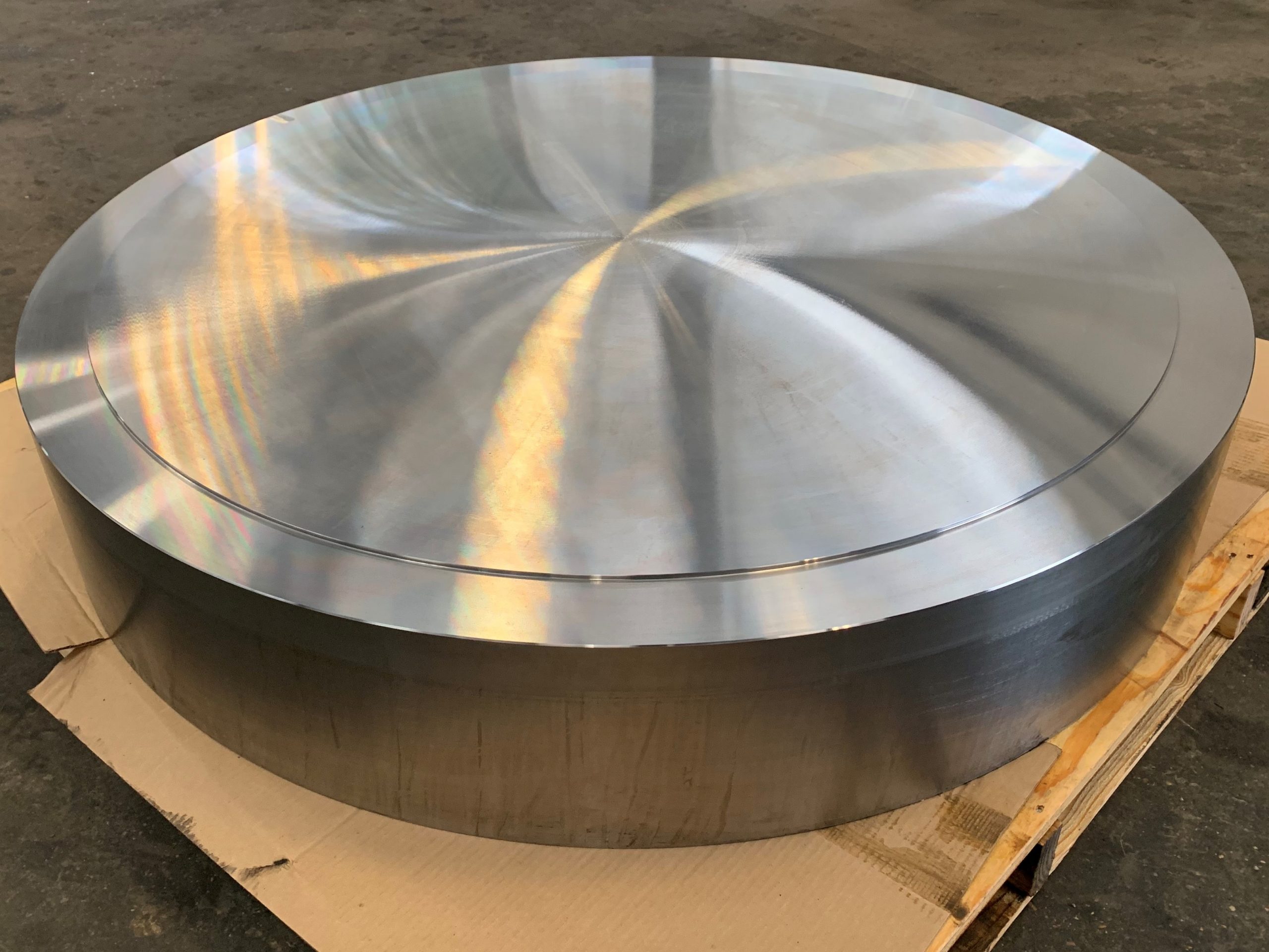

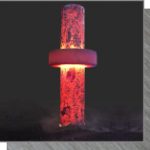

Forged Discs

A forged disc is made by upsetting or standing preheated piece of raw material on end and forging it between the upper and lower dies. The upset process induces directional grain flow, which gives strength, ductility and increased resistance to impact and fatigue not found in plate or bar stock.

Forged discs are renowned for their exceptional strength and durability, and this holds true for all forgings. When compared to alternative metal forming techniques like burning out plate, forged discs and blanks exhibit a superior microstructure, further contributing to their toughness.

Forged discs are used for a variety of general industrial equipment and machinery used by the steel, power generation and power transmission industries. Some of the common uses for our forged discs are blind flanges, tube sheets, gears, etc. for the oil field and automotive applications.