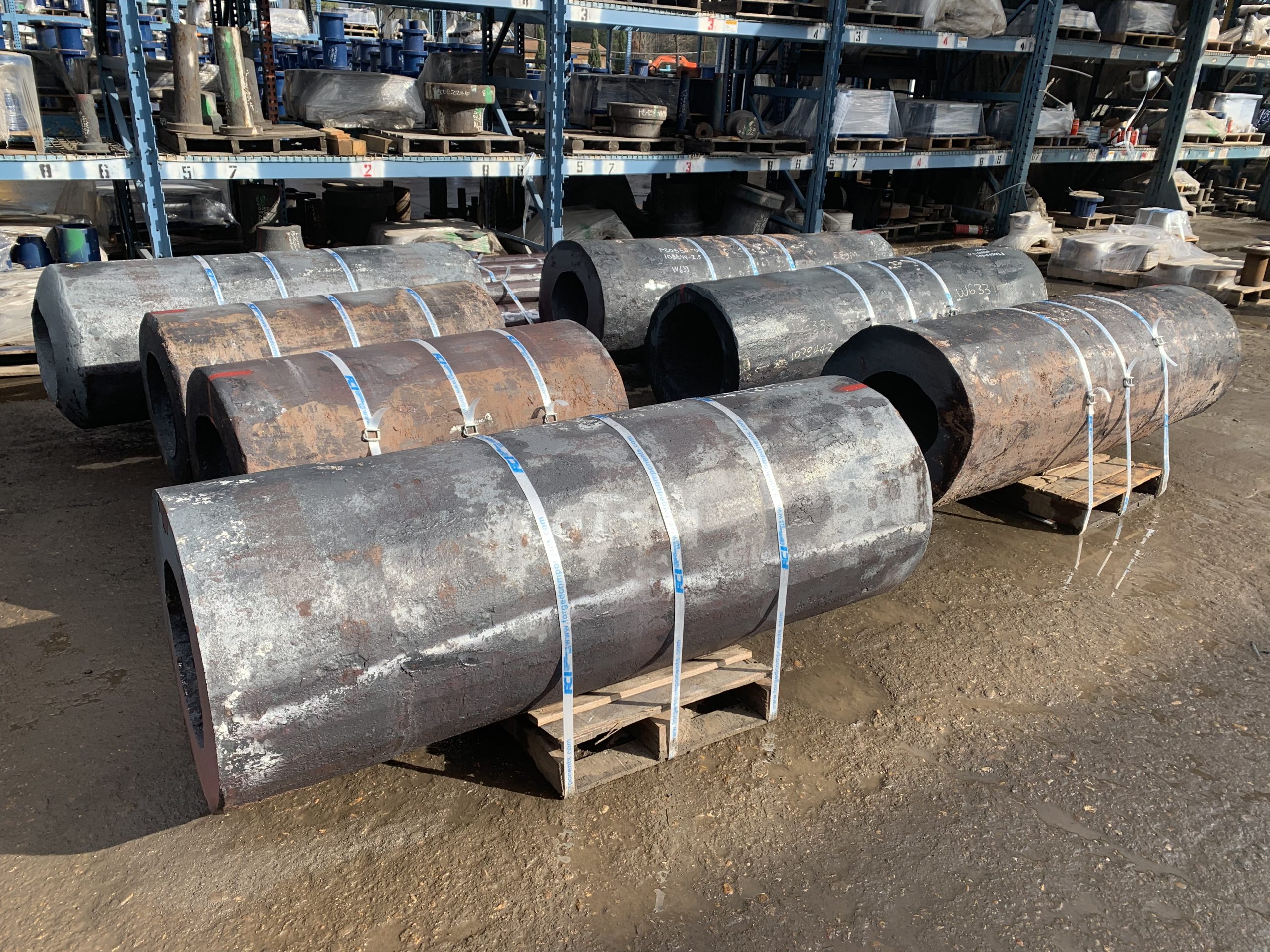

Forged Cylinders

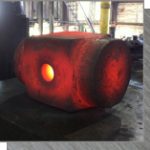

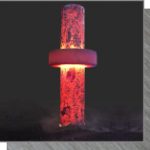

Forging of a cylinder begins by making an upset preform, then punching a hole through the center. The mandrel gets inserted into the created bore and the material gets drawn out to the specified length and OD/ID configuration.

We manufacture seamless, heavy wall forged rings and cylinders in a variety of customized configurations as per customer requirements. The cylinders are ideal for high-stress applications and harsh environments due to their durability and strength. They can be produced not only in a straight cylindrical shape, but with unlimited variations of ODs and IDs, including tapers.

FCI can manufacture cylinders with a maximum OD of 110 inches and length of 140 inches up to 55,000 pounds in weight. The cylinders can be produced with square ends, butt-weld ends, with closed ends and holes drilled.