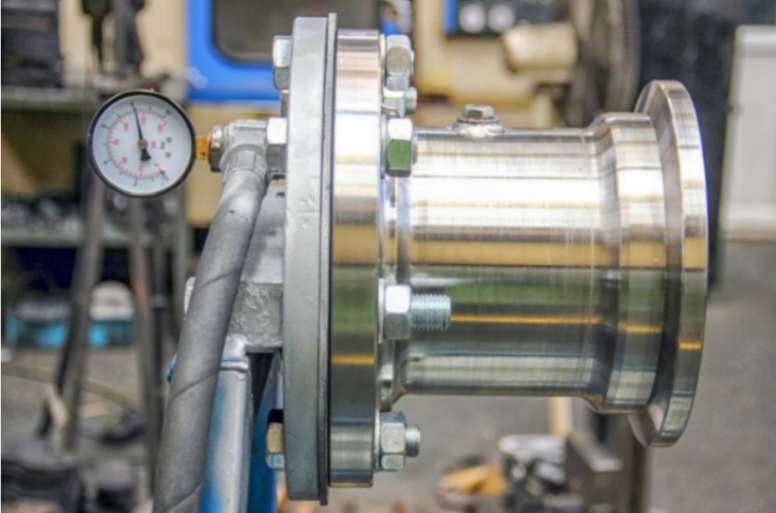

Components of a Forged Pressure Vessel

Forged pressure vessels are designed to contain gases or liquids at pressures substantially different from ambient pressure. They are used in the oil, gas, chemical and petrochemical industries. The construction of a forged pressure vessel involves several components, each serving a specific function to ensure the vessel operates safely and efficiently. Here are the primary parts of a forged pressure …