What are API Flanges? How They Work Explained

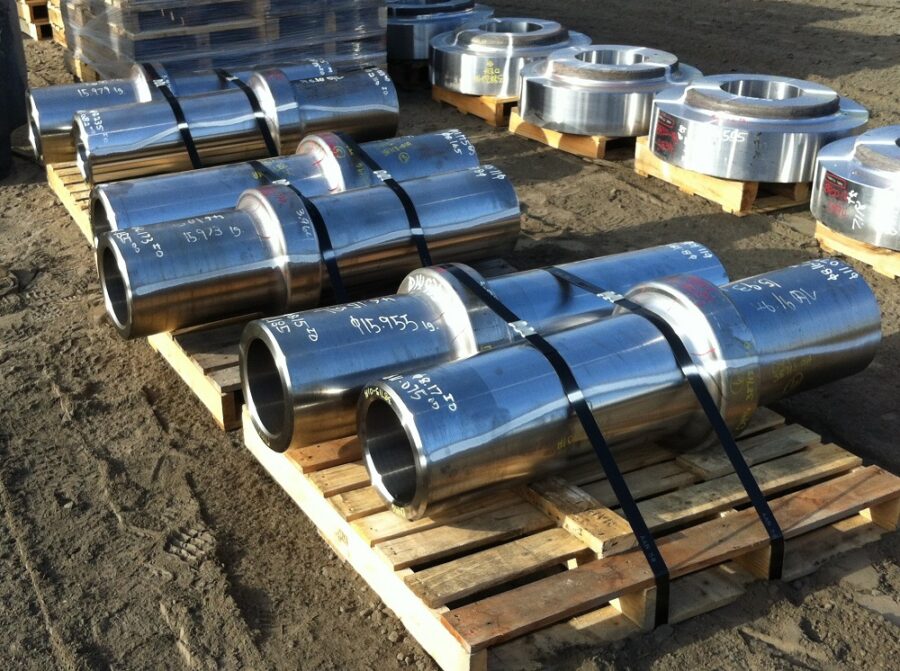

API forged flanges are highly useful for applications that include building projects and industrial processes conducted by refineries. The term API is short for the American Petroleum Institute. These highly useful flanges differentiate from other types, such as the ANSI/ASME variety. API flanges are designed to handle a higher-rate of pressure and temperature. API flanges are the better choice for …