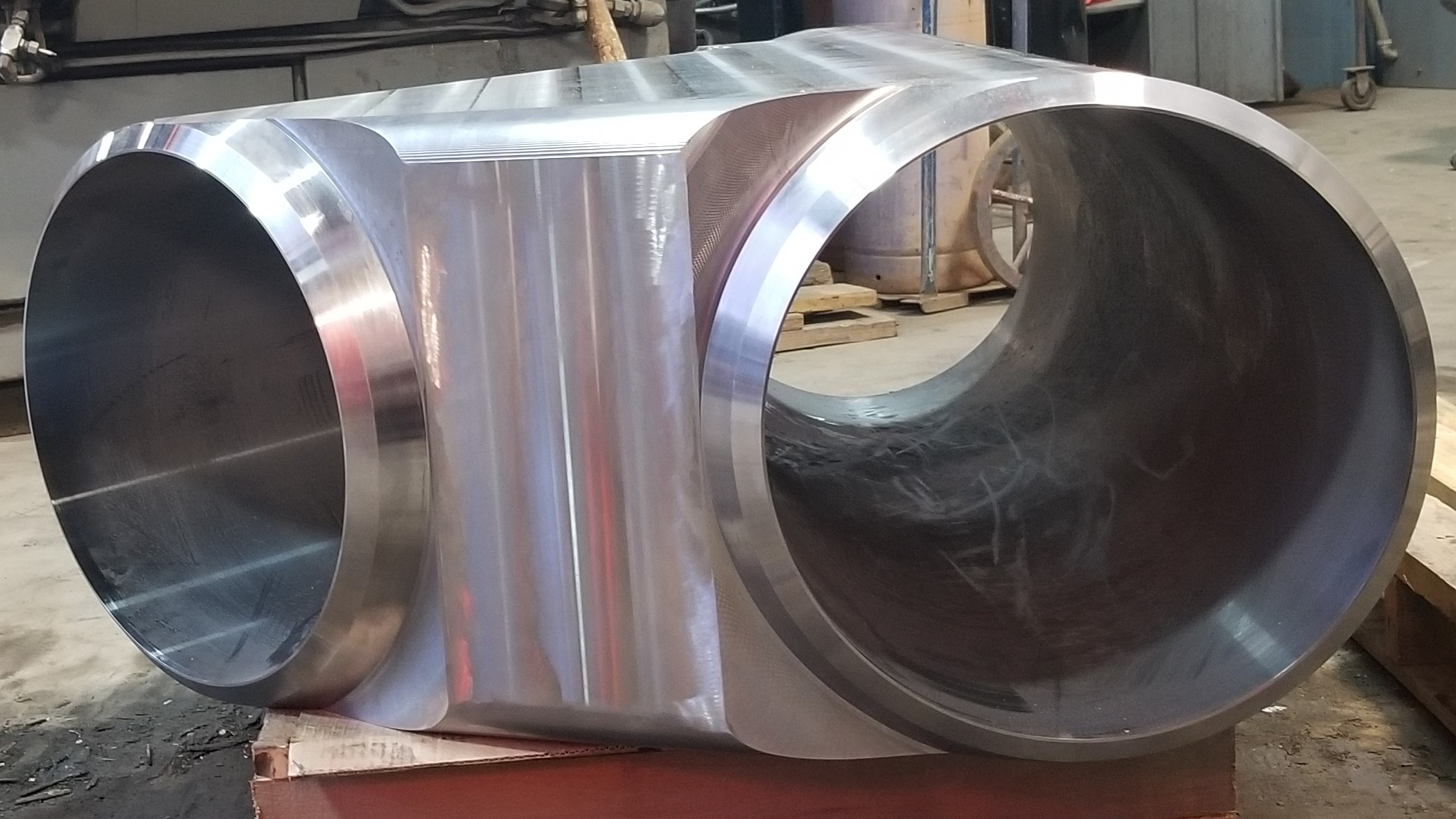

Forged Heavy Wall Fittings

FCI manufactures forged heavy wall fittings in a finished condition for the power generation industry, primarily for the coal-fired and gas power plants throughout the North America. These fittings are typically forged out of chrome moly alloy material that is designed to withstand high pressure and high temperature environment.

Once our fittings are delivered to the customer, welded into the piping system that is tested and ultimately delivered to the power plant for either of the following scenarios:

- Repair of an existing system

- Conversion from coal to gas

- New construction of a power plant

Our forged power fittings are produced strictly on make to order basis. We have a large experience in manufacturing these critical products to the customers’ technical requirements, while maintaining our delivery commitments.

Here are some key features and characteristics of forged heavy wall fittings for the power generation industry:

Material: The forged fittings are often made from high-quality materials such as carbon steel, stainless steel, or alloy steel to ensure durability and resistance to corrosion.

Forged Construction: These fittings are manufactured through forging, a process that increases the strength and integrity of the material compared to cast or welded fittings. Forging involves shaping metal while it's in a heated, malleable state under high pressure, resulting in a stronger and more uniform structure.

Heavy Wall Thickness: The fittings have thicker walls compared to standard fittings, providing additional strength and reliability, particularly in high-pressure applications.

Precision Machining: After forging, the fittings undergo precision machining to achieve the required dimensions and tolerances, ensuring proper fit and function in the power generation system.

Pressure Ratings: They are designed to meet or exceed industry standards for pressure ratings, ensuring their suitability for high-pressure piping systems commonly found in power plants.

Corrosion Resistance: Special coatings or treatments may be applied to the fittings to enhance their resistance to corrosion, extending their service life in harsh operating environments.

Variety of Configurations: These fittings come in various configurations such as elbows, tees, reducers, couplings, and flanges, allowing for the construction of complex piping systems tailored to the specific needs of power generation facilities.

Compliance: They are typically manufactured to comply with relevant industry standards and regulations, such as ASME (American Society of Mechanical Engineers) standards for pressure piping systems.

All the manufacturing processes are completed strictly in-house, allowing us the most flexibility and efficiency when it comes to completing any customer order. Starting with a strategic and metallurgical approach to raw material selection to forging, heat treating, machining and NDE; we ensure the finished product meets the highest quality standards, as well as a timely delivery.