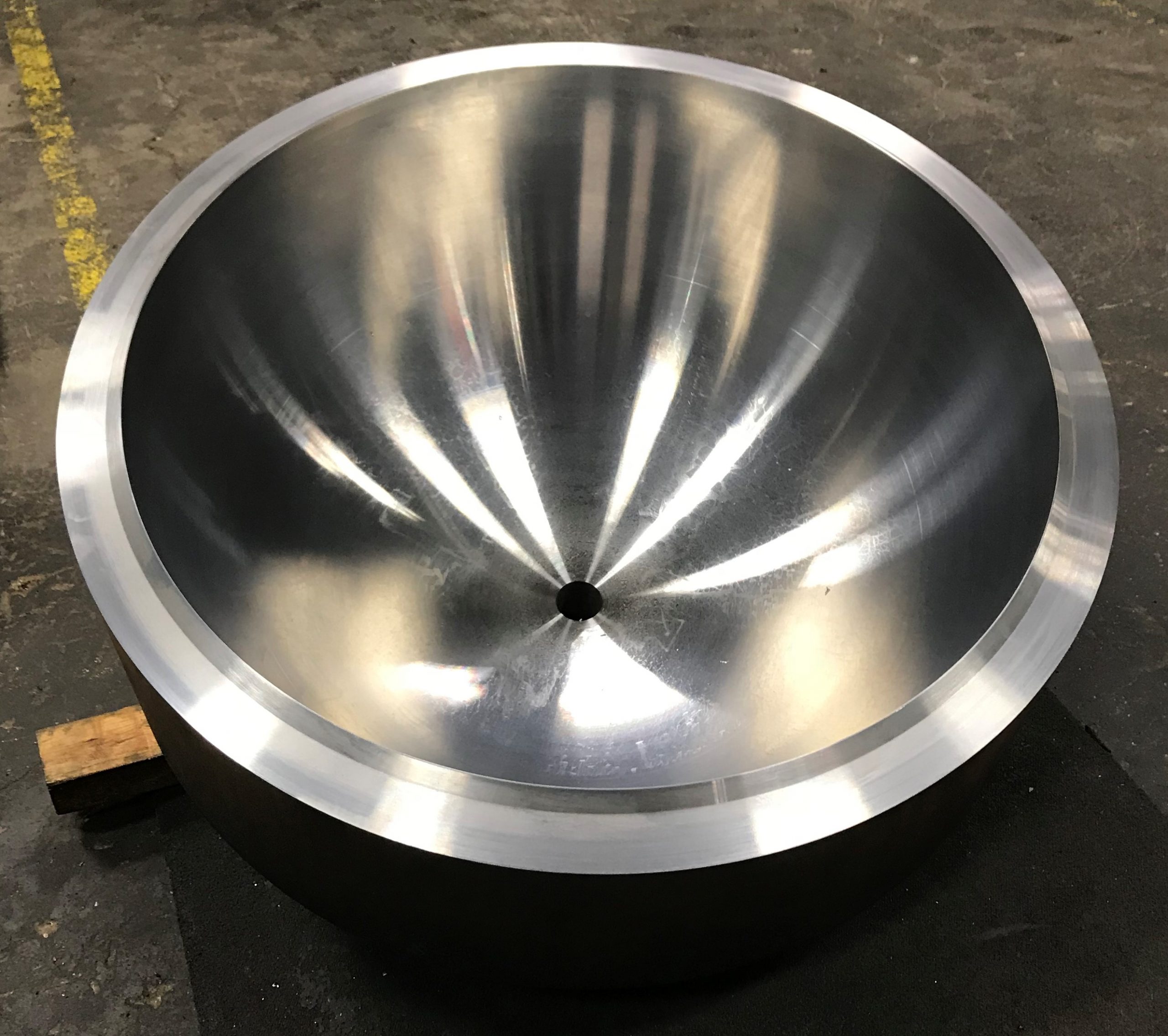

forged HEMI HEADS

Forged hemi-heads are widely used across various industries due to their strength, durability, and effectiveness in handling high-pressure environments. The industries and specific applications include:

Oil & Gas Industry

Pressure Vessels: Used in separators, scrubbers, and other types of pressure vessels that require robust construction to handle the separation processes under high pressures.

Storage Tanks: For storing petroleum products and natural gases under pressure.

Reactors: In refining processes where chemical reactions occur under pressure.

Chemical Processing Industry

Reactors: For chemical reactions that occur under pressure, providing safety and efficiency.

Process Vessels: Where chemicals are stored or processed under pressure, hemi-heads help maintain the integrity of the vessel.

Power Generation Industry

Boilers: Employed in boiler drums where steam is generated under high pressure.

Nuclear Reactors: In the construction of containment vessels for nuclear reactors, where extreme pressure and temperature resistance are required.

Pharmaceutical Industry

Bioreactors: Where cultures or chemical reactions require precise control of pressure.

Process Vessels: Used for the safe processing and storage of pharmaceutical products under controlled pressures.

Food & Beverage Industry

Fermentation Tanks: Utilized in tanks where fermentation processes occur under pressure.

Storage Tanks: For carbonated beverages or other products requiring pressure containment.

Aerospace & Defense

Pressure Vessels: For aerospace applications where equipment must withstand the extreme pressures and temperatures of space or high-altitude environments.

Fuel Tanks: Particularly in military applications where robust and secure fuel storage is critical.

Water Treatment

Pressure Vessels: Used in high-pressure water treatment applications, such as reverse osmosis plants.

Shipbuilding

Pressure Vessels: For on-board systems that operate under high pressures, such as compressed air systems.

Key Characteristics and Benefits

Durability: Forged hemi-heads are incredibly durable due to the forging process, which aligns the grain flow of the metal, enhancing its strength.

Pressure Resistance: The hemispherical shape is ideal for evenly distributing stress, making these heads suitable for high-pressure applications.

Customization: These components can be customized during the forging process to meet specific industry needs, including size and material properties.

These versatile applications highlight the critical role forged hemi-heads play in many sectors, primarily due to their ability to efficiently handle high pressures and adverse conditions.