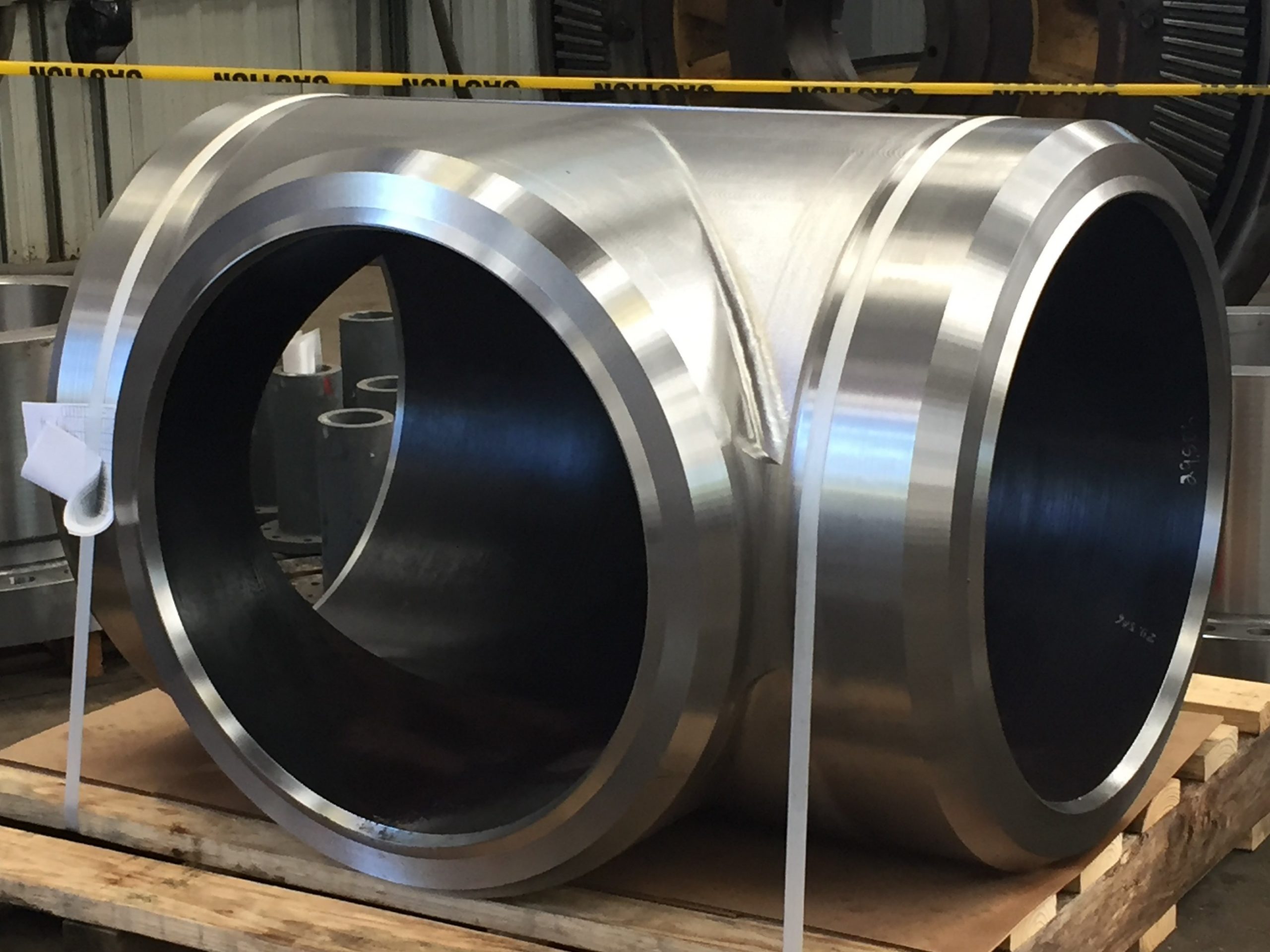

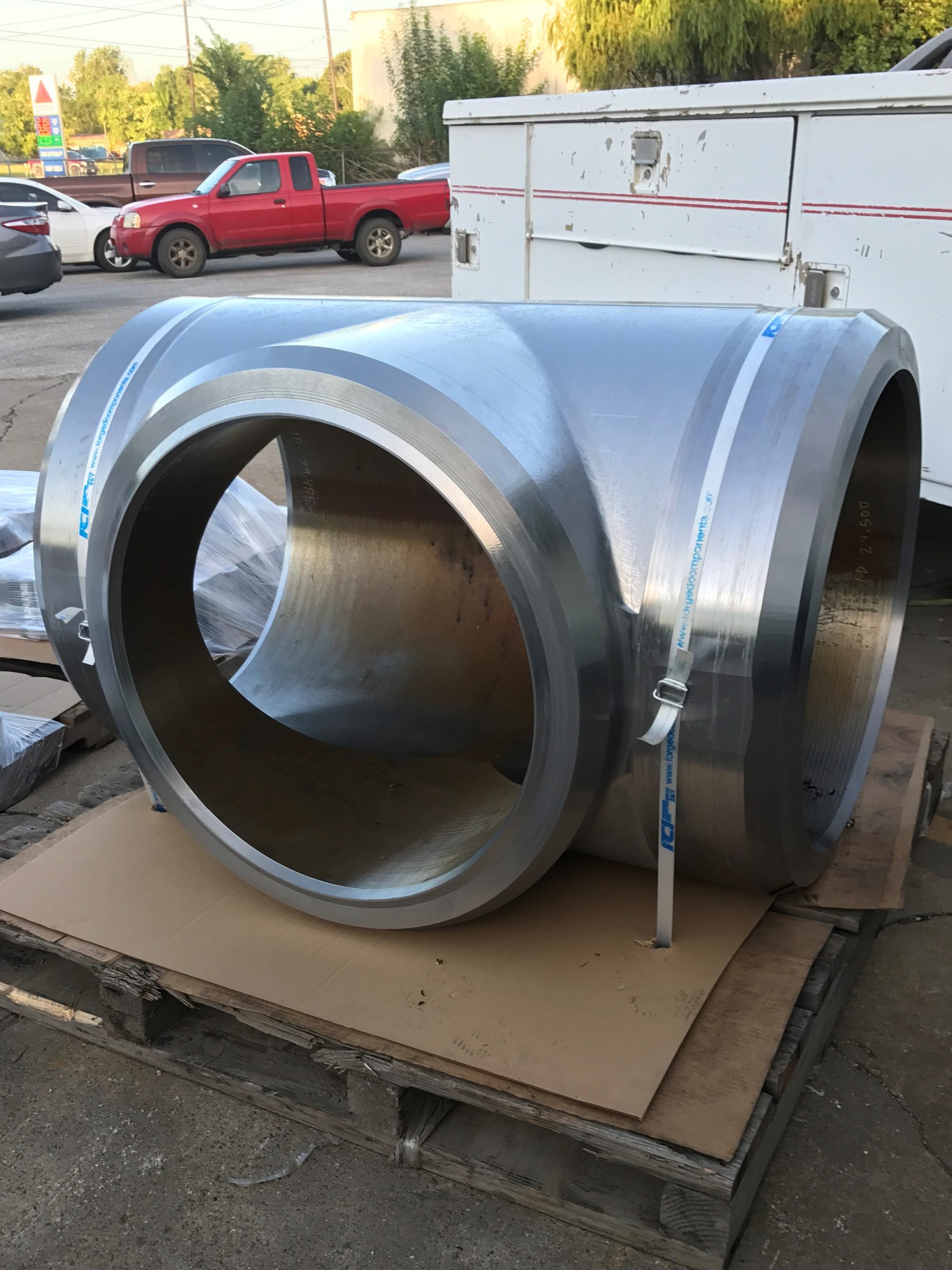

Forged TEES

Forged tees are pipe fittings used extensively in the piping systems of the oil, petrochemical, and gas industries. They are created through the process of forging, which involves shaping metal under high pressure or impact, resulting in a component with superior strength, durability, and resistance to impact and fatigue compared to those made by casting or machining.

Types & Features

Equal Tees: These have the same size on all three ends and are used to divide the flow equally from one pipe into two directions or combine flow from two directions into one.

Reducing Tees: These have one branch smaller in size than the main line. They are used to connect pipes of different sizes and are particularly useful in tight spaces where reducers and separate tees might not fit.

Materials: Forged tees are typically made from carbon steel, stainless steel, alloy steel, and other materials suitable for the specific requirements of the industry, such as high temperature and corrosion resistance.

Applications in Oil, Petrochemical, and Gas Industries

Pipeline Systems: Forged tees are used in the pipeline systems for transporting crude oil, natural gas, and petrochemical products. They are essential for branching off main pipelines or for integrating additional pipes into existing systems.

Process Piping: In refineries and petrochemical plants, forged tees are utilized within the process piping systems that carry fluids, gases, and slurries. They are crucial for directing flow, integrating instrumentation, and facilitating maintenance and expansion of the system.

High-Pressure Environments: The superior strength of forged tees makes them ideal for high-pressure applications, ensuring safety and reliability in the critical environments of the oil, gas, and petrochemical industries.

Temperature Resistance: Forged tees can withstand extreme temperatures, making them suitable for the thermal variations encountered in processing and refining operations.

Corrosion Resistance: Materials used for forged tees can be selected based on their resistance to corrosion caused by the harsh chemicals and environments present in these industries.

Safety and Reliability: The forging process enhances the mechanical properties of the tees, ensuring they can withstand the operational stresses and hazards associated with oil, gas, and petrochemical operations, thus contributing to the overall safety and reliability of the systems.

Forged tees play a critical role in the infrastructure of the oil, petrochemical, and gas industries, providing flexibility in piping system design, ensuring reliability under high-pressure and corrosive conditions, and facilitating safe and efficient transport and processing of valuable resources.

FCI is a manufacturer of tees, which are heavy wall fittings for the power generation industry for coal-fired and gas power plants throughout North America.