The Process And Materials Required For Seamless Rolled Ring Forging

The forgings for carbon steel are a part of our lives whether we are aware of it or not. This particular material has many uses and comes in four grades. Each grade has a different purpose.

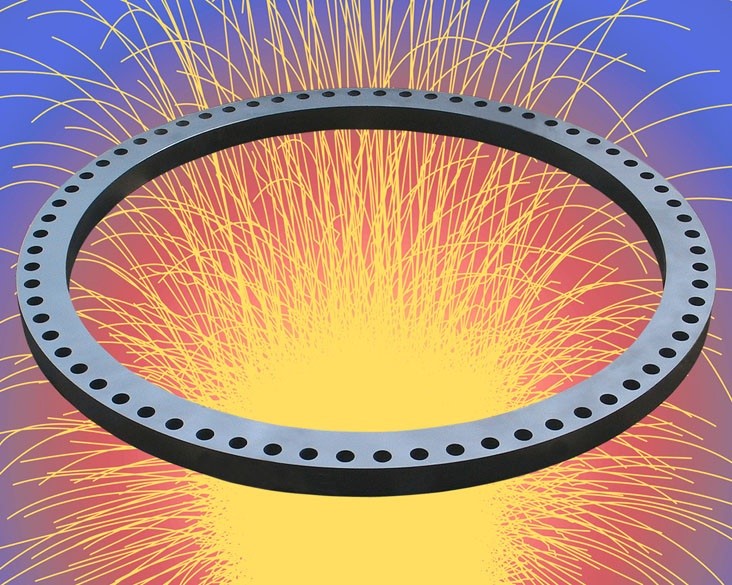

The aerospace industry uses a process called seamless ring rolling forging. This involves punching a hole into a piece of metal with a good thickness so it becomes shaped like a donut. These pieces are then put through a process where they are squeezed and rolled and turned into a ring.

This process is also used to add strength for certain component’s that resist pressure. A good example is the engines used in aircrafts or wheel bearings. This process is critical for these components.

The Material

The difference in seamless rolled ring forging is reliant on the material used. The ability to resist wear, strength and the hardness are all extremely important factors. Most important is resisting wear since many of the products are used in machines and engines. They are exposed to high temperatures and must be able to sustain the heat.

The strength of the material upon impact is also key. A lot of these products are used in work considered to be heavy duty. When parts collide, the material can’t buckle with the impact.

Hardness is another critical factors in the material. Most material is made of carbon although many use only a small fraction. A low carbon ration means the material is labeled as low but will work very well for forging.

The Products

Some of the most common products are components for machinery, equipment for mining and oilrigs and bushings. Almost anything can be made with a forge and then shaped. Most factories use specialized equipment so it is able to withstand the high levels of heat.