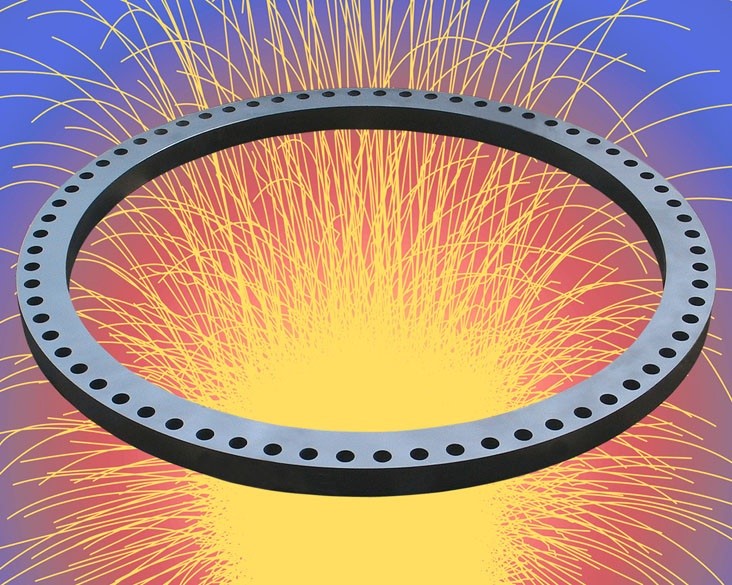

The Process And Materials Required For Seamless Rolled Ring Forging

The forgings for carbon steel are a part of our lives whether we are aware of it or not. This particular material has many uses and comes in four grades. Each grade has a different purpose. The aerospace industry uses a process called seamless ring rolling forging. This involves punching a hole into a piece of metal with a good …