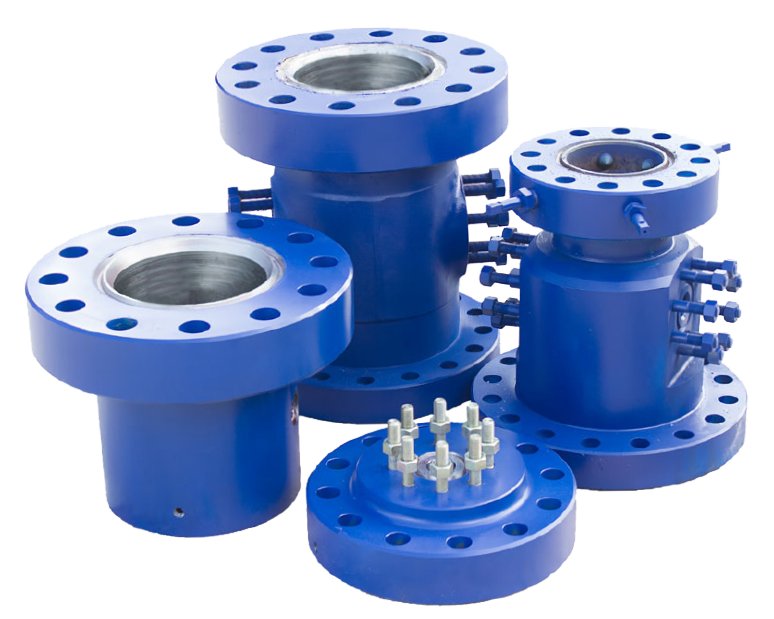

Wellhead Products

FORGED Tubing Heads

A tubing head is a wellhead component consisting of a body with two flanges, that support the tubing hanger, and provide a means of attaching the Christmas tree to the wellhead. It seals off the pressure between the casing and tubing annulus and connects with the tubing adapter on the top.

The tubing head is the topmost spool in a wellhead assembly and is responsible for supporting and sealing the tubing string. The upper section of the tubing head has a straight-shaped bowl and a 45-degree load shoulder that helps support and seal the tubing string through a tubing hanger.

A forged tubing head is used in oil and gas wellheads and is designed to perform several important functions:

Pressure Containment: The primary function of a forged tubing head is to provide pressure containment for the wellbore. It is located at the top of the wellhead and is responsible for maintaining the integrity of the well under high-pressure conditions.

Tubing Hanger Support: The tubing head provides support and attachment points for the tubing hanger, which is a component that holds and seals the production tubing in place. The tubing hanger allows for the flow of fluids from the wellbore to the surface.

Sealing and Isolation: The tubing head typically includes seals and gaskets that provide a reliable barrier to prevent the escape of well fluids, such as oil and gas, into the surrounding environment. It also isolates different zones within the wellbore, helping to control and manage the flow of fluids from various reservoirs.

Connection Point: The forged tubing head serves as a connection point for other wellhead components, such as the casing head, casing spools, and blowout preventers. It allows for the installation of additional equipment and tools as needed during well operations.

Pressure Monitoring and Control: Some tubing heads may include pressure monitoring and control features, such as valves and gauges, to enable operators to monitor and adjust pressure levels in the well as necessary for safe and efficient production.

Wellhead Maintenance and Accessibility: The design of the tubing head allows for easy access to the tubing and wellbore for maintenance, repair, and intervention activities.

Overall, a forged tubing head plays a crucial role in the safe and efficient operation of oil and gas wells, ensuring that pressure is contained, fluids are controlled, and maintenance can be performed when needed. These components are typically made from high-strength materials and are subjected to rigorous quality and safety standards to withstand the demanding conditions encountered in the oil and gas industry.