What Are Some of the Most Common ANSI Flanges?

The oil, gas, and petrochemical industries use many different types of ANSI flanges for piping systems, with each type used in specific situations in order to maximize the life of the flange, ease of installation, and overall cost.

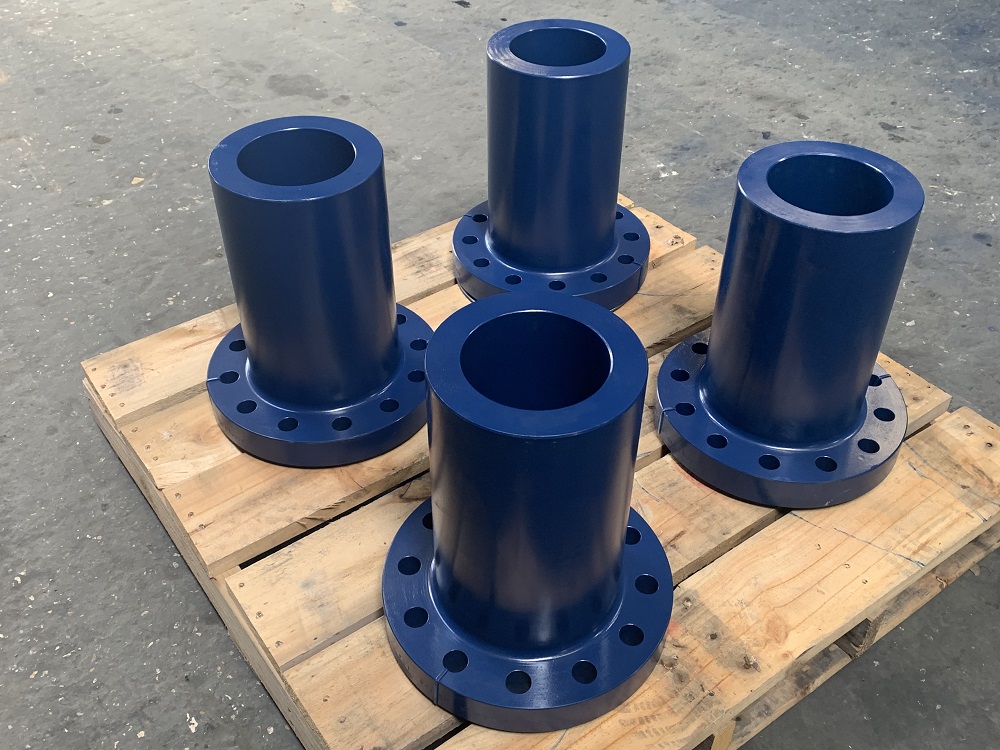

Long Weld Neck Flanges

The long weld neck flange is the standard against which all other ANSI flanges are measured when it comes to strength and wear life. Long weld neck flanges are the standard because they are used for many different high-pressure applications at a variety of extreme temperatures and are designed to limit turbulence and erosion at the joint.

Blind Flanges

Blind pipe flanges seal off pipes, valves, and ASME pressure vessel openings while providing an option to expand the pipeline network in the future. These flanges are also often used for high-pressure testing within the pipeline network.

Large Diameter Flanges

Large diameter flanges are simply other flange types, such as long weld-neck flanges and blind flanges that are designed for a much larger size than typical flanges. These are necessary because there are a lot of different nominal pipe sizes out there, and some of them require flanges that with a larger diameter to work with these larger pipe sizes.

Slip-On Flanges

In general, these flanges are rated at about two-thirds of the strength of a standard long weld neck flange and they have a fatigue life of about one-third of that of a comparable long-weld neck flange. They are connected to pipes using two filet welds, one at the outside of the flange and another at the inside of the flange. This makes them a bit more time consuming to install on a pipe, as well as reduces the versatility of the flange because combining them with elbow and tees is not possible. All fittings used with slip-on flanges must have a straight end.

Socket Weld Flanges

Socket weld flanges are just about as strong as slip on flanges, but are about 50% stronger when it comes to resisting fatigue. These flanges are attached using a single fillet weld on the outside of the flange. This makes them less labor intensive to install.

Threaded Flanges

The best thing about threaded flanges is that they can be installed into a pipe system without welding. These are used for smaller pipe sizes most of the time and only for pipe systems that have thick walls.

Forged Components is the Premier Manufacturer of ANSI Flanges

We are one of the world’s leading manufacturers of ANSI flanges including long weld neck flanges, blind flanges, and large diameter flanges (just to name a few). So, why not buy them from the industry leader: Forged Components? For more information, call us at (281) 441-4088 or contact us online to get a quote from our sales staff.