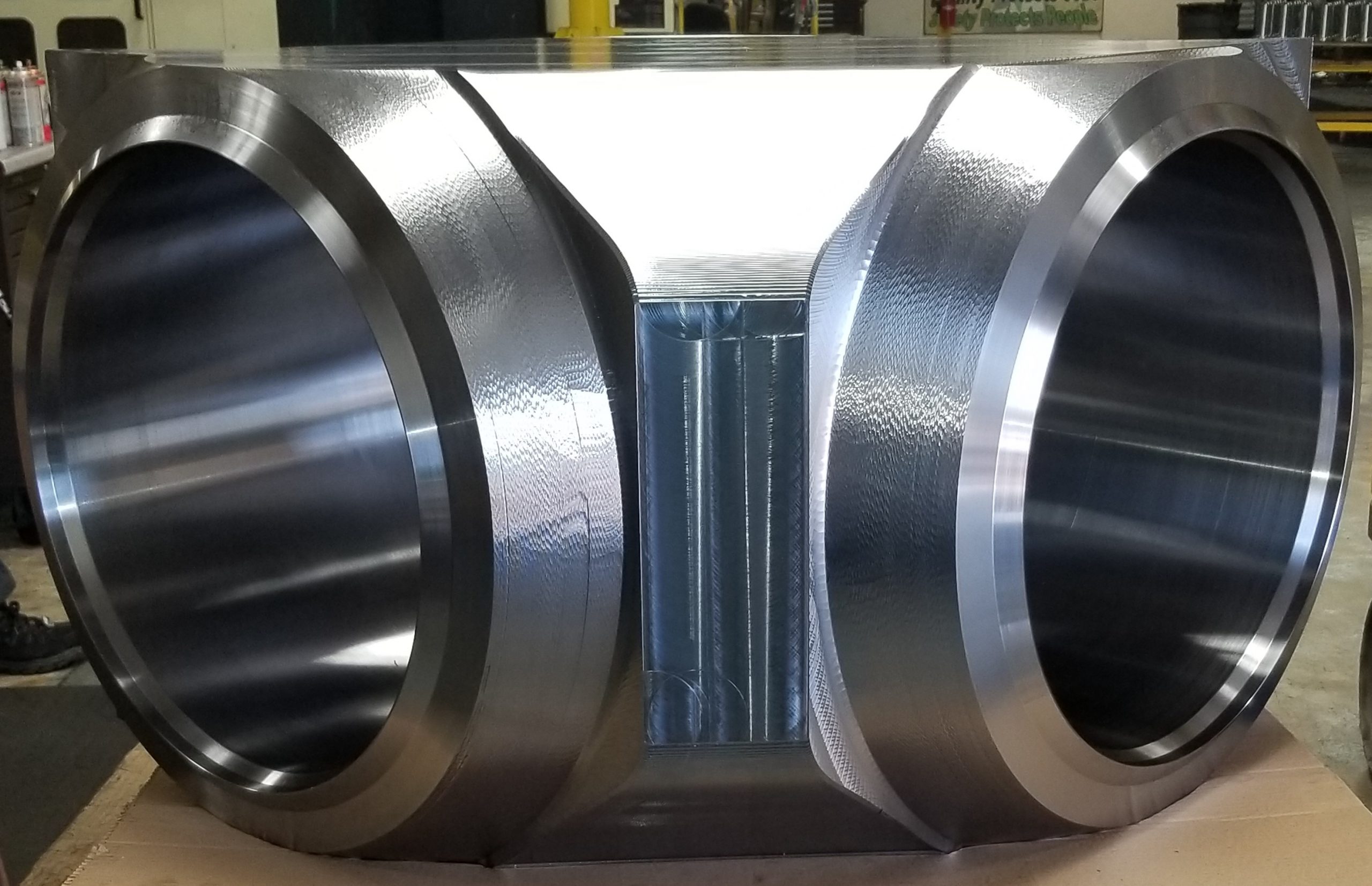

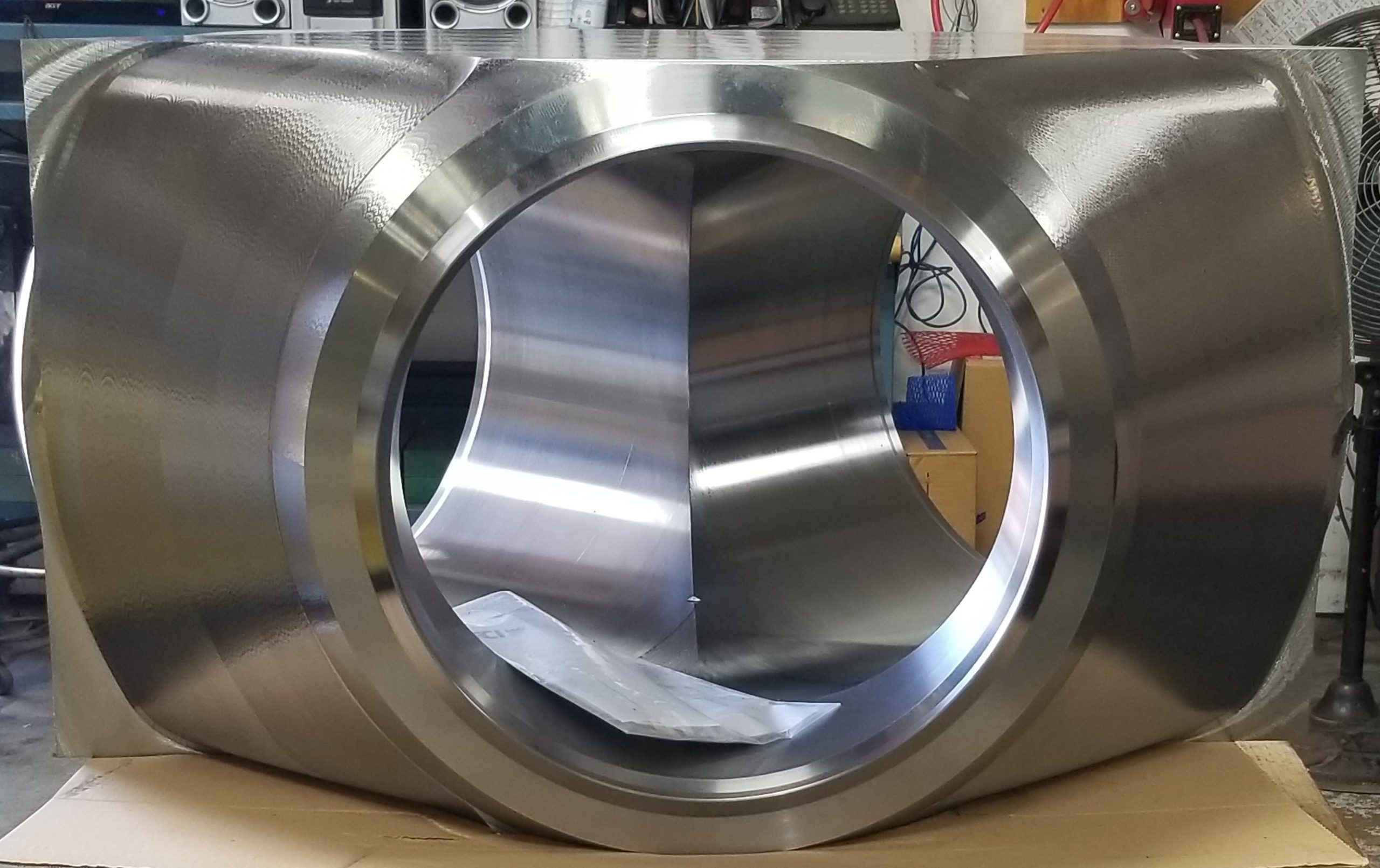

Forged Wyes Fittings

Forged wyes are specialized fittings used in piping systems to create branch connections at an angle from the main pipeline. They are typically used in applications where a branch line must be connected to a main pipeline at an angle, such as in plumbing, oil and gas, chemical processing, and other industrial settings.

Forged wyes are constructed through a forging process, which involves shaping metal under high pressure and temperature to achieve the desired shape and properties. Here are some key features and characteristics of forged wyes:

Branch Connection: A forged wye features a branch connection that is angled from the main pipeline. This allows for the diversion of flow or the connection of a branch line to the main pipeline.

Reinforced Design: To withstand the stresses and pressures encountered in piping systems, forged wyes are typically designed with reinforced walls and integral reinforcement at critical points.

High-Quality Materials: They are commonly made from materials such as carbon steel, stainless steel, or alloy steel to ensure durability, corrosion resistance, and suitability for various operating conditions.

Precision Machining: After the forging process, forged wyes undergo precision machining to achieve the required dimensions, tolerances, and surface finish.

Pressure Ratings: They are designed to meet or exceed industry standards for pressure ratings, ensuring their suitability for use in high-pressure piping systems.

Variety of Sizes and Configurations: Forged wyes are available in a variety of sizes and configurations to accommodate different pipe diameters and branch line requirements.

Compliance: They are manufactured to comply with relevant industry standards and specifications, such as ASME (American Society of Mechanical Engineers) standards for pressure piping systems.

Application Flexibility: Forged wyes can be used in a wide range of applications, including but not limited to, oil and gas transmission, chemical processing, water distribution, and HVAC systems.

Overall, forged wyes play a crucial role in piping systems by facilitating branch connections at specific angles while maintaining structural integrity and ensuring efficient fluid flow.

We manufacture finished forged wyes fittings for the power generation sector, focusing mainly on coal-fired and gas power plants in North America. These fittings are usually crafted from chrome moly alloy to endure extreme pressure and temperature conditions.