Guide to Weld Neck Flanges and How They Help in Pipelines

Weld neck flanges are an essential component in pipelines, as they provide a secure and reliable connection for the pipeline. This guide will teach you what you need to know about weld neck flanges and how they can benefit your oil and gas industry pipelines.

What are Weld Neck Flanges & Why You Should Invest in Them

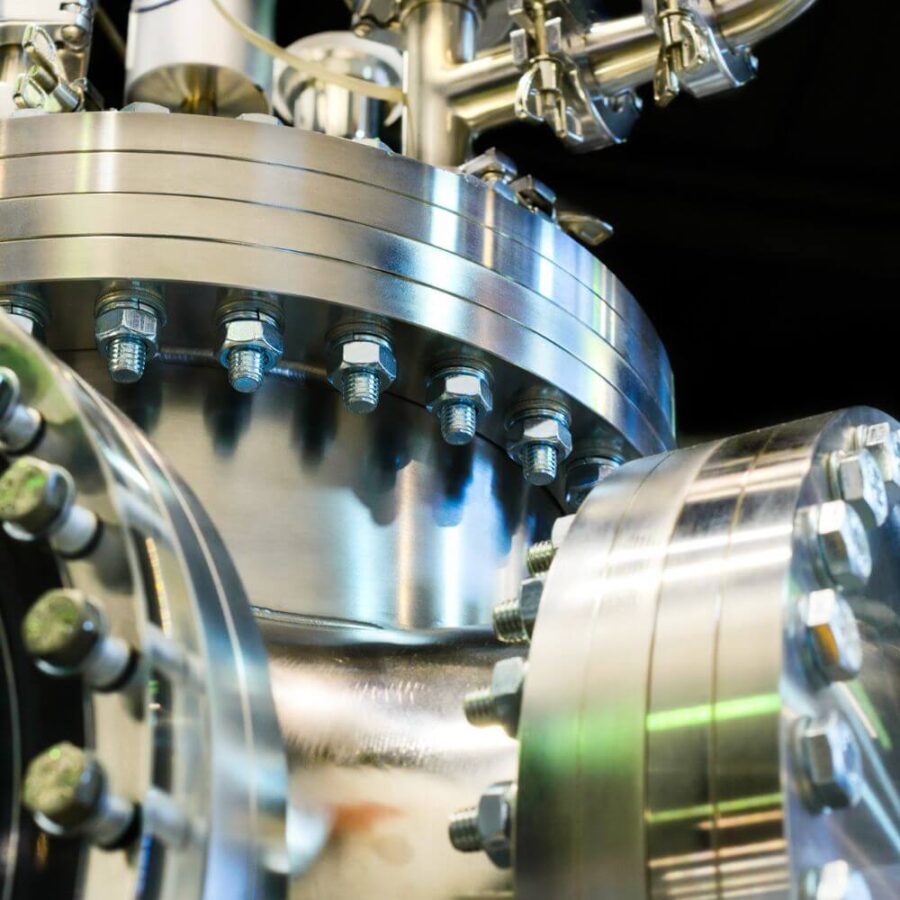

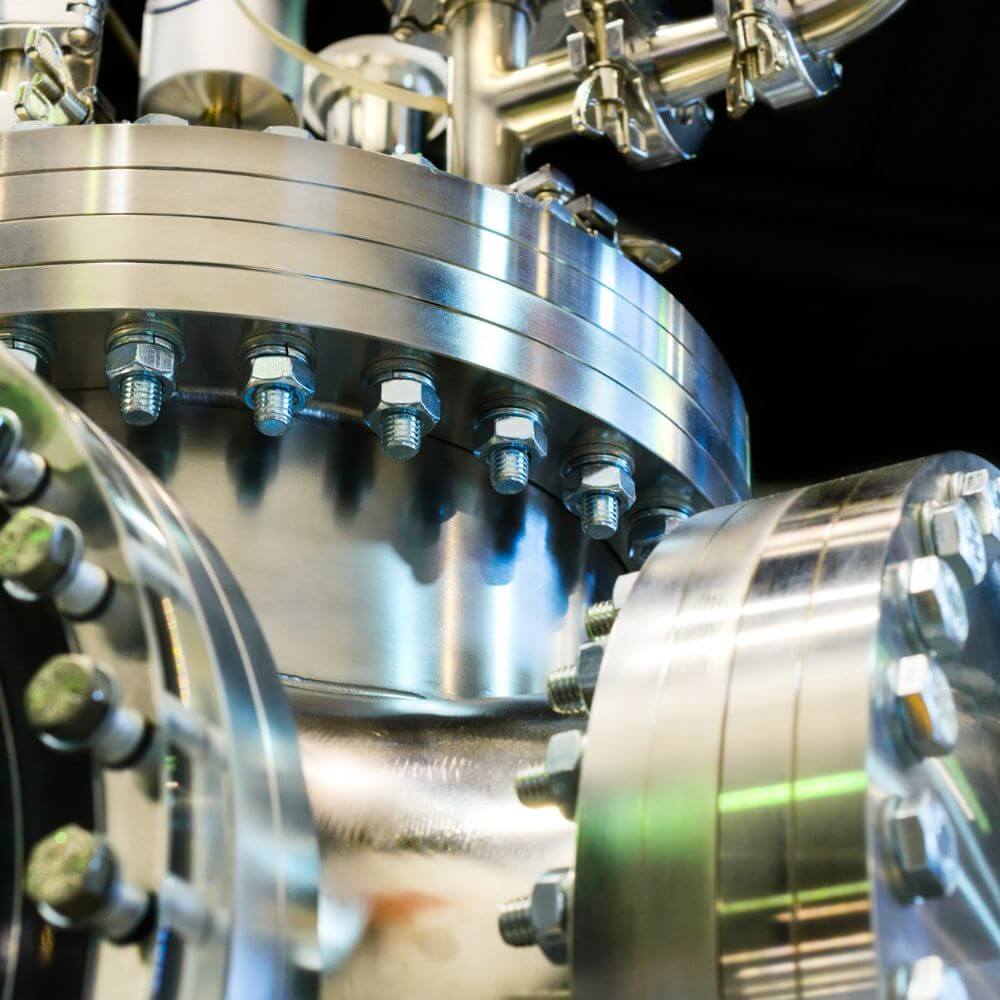

Weld neck flanges are pipe flanges designed to be welded to a pipe. They are typically used in high-pressure, high-temperature piping systems and are known for their ability to handle high stress-levels.

Weld neck flanges are characterized by a long-tapered hub and a beveled end that is meant to be welded to a pipe. They are often used in conjunction with a gasket and bolts to create a seal between two pipes, a pipe, a valve, or other equipment.

Weld neck flanges are known for their strength and durability and are often used in piping systems that carry hazardous materials. They are also used in piping systems that require frequent cleaning or maintenance, as they can be easily removed and replaced without having to cut or alter the pipe.

What are the Top 5 Reasons Weld Neck Flanges are the Best for the Oil and Gas Industry

Here are the top five reasons why weld neck flanges are often considered the best choice for use in the oil and gas industry:

- Handles High Stress Levels – Weld neck flanges are known for handling high-stress levels, making them ideal for high-pressure, high-temperature piping systems. This makes them well-suited for use in the oil and gas industry, where pipes may be subjected to extreme conditions.

- Easy to Remove – Weld neck flanges can be easily removed and replaced without cutting or altering the pipe, making them easy to maintain and service. This is especially useful in the oil and gas industry, where pipes may be located in remote or hard-to-reach areas.

- Versatile for Different Industries – Weld neck flanges can be used in various applications and industries, including oil and gas, chemical processing, water treatment, and power generation. This makes them a suitable choice in the oil and gas industry, where various piping systems may be required.

- Reliable – Weld neck flanges are known for their reliability, which makes them a good choice for use in critical piping systems or applications where failure is not an option. In the oil and gas industry, where safety is of the utmost importance, weld neck flanges can be an excellent choice.

- Easily Customizable – Weld neck flanges can be customized to meet the specific needs of the oil and gas industry, including special materials, coatings, and dimensions. This allows them to be tailored to the requirements of a given project or application.

What Designs of Weld Neck Flanges Does the Oil and Gas Industry Use?

The oil and gas industry uses weld neck flanges in a wide variety of designs, depending on the application’s specific needs. Some standard designs include:

- Slip-on weld neck flanges:These flanges are designed to slide over the end of a pipe and are typically used in low-pressure piping systems.

- Threaded weld neck flanges:These flanges have threads on the inside of the flange, allowing them to screw onto the end of a pipe. They are often used in low-pressure piping systems or where the flange must be removed frequently.

- Socket weld neck flanges:These flanges have a small recess on the inside of the flange, allowing them to be welded to a pipe using a socket weld. They are often used in high-pressure piping systems.

- Lap joint weld neck flanges: These flanges have a stub end welded to the pipe, with the flange itself attached using a lap joint. They are often used in low-pressure piping systems or where the flange must be removed frequently.

- Blind weld neck flanges:These flanges are used to close the end of a pipe and do not have a through a hole. They are often used in high-pressure piping systems or situations where the pipe’s end needs to be sealed.

The specific design of the weld neck flange used in the oil and gas industry will depend on the application’s requirements, including the pressure and temperature of the piping system, the materials being transported, and the need for ease of maintenance or customization.

ANSI Flanges for the Oil and Gas Industry

ANSI flanges are a type of pipe flange designed to meet the standards set by the American National Standards Institute (ANSI). These standards cover various dimensions, materials, and design features for pipe flanges and other piping components.

The oil and gas industry often requires using ANSI flanges, as they provide a consistent, reliable, and safe way to connect pipes and other piping components. ANSI flanges are widely used in the industry due to their high standardization level, making it easy to select the correct flange for a given application.

ANSI flanges are available in various designs, including weld neck flanges, slip-on flanges, threaded flanges, and lap joint flanges. The specific design of ANSI flange used in the oil and gas industry will depend on the application’s requirements, including the pressure and temperature of the piping system, the materials transported, and the need for ease of maintenance or customization.

Contact Our Team About Weld Neck Flanges for the Oil & Gas Industry

We’re a leading manufacturer of forged components and offer custom designs and options to suit your needs. Contact us at (281) 441-4088 or send us a quote online to find out about our custom designs and opportunities to meet your requirements.