Why Work with a Professional Forged Flanges Manufacturer?

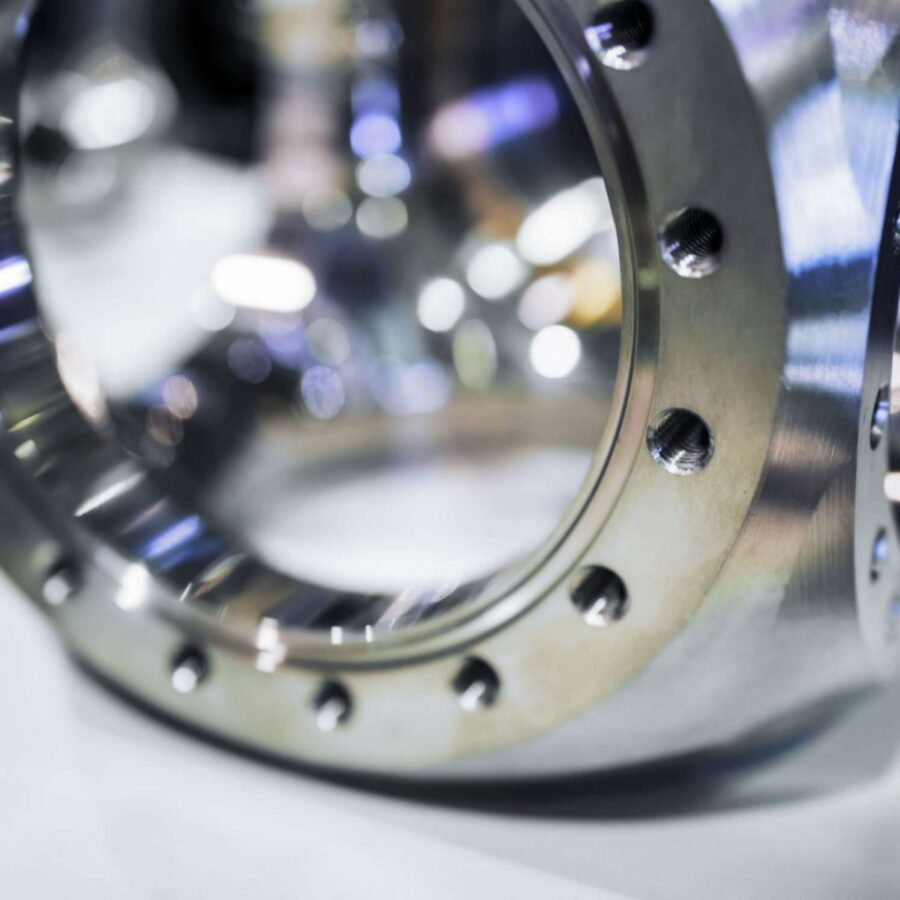

Forged flanges are essential components in a wide variety of industrial applications. They provide a secure connection between two pieces of piping, and also help control the pressure and flow of liquid or gas through a pipe. Working with a reliable professional manufacturer is critical to ensuring these parts are accurately fabricated and hold up to the demands of their intended environment.

Understand the Different Types of Forged Flanges and Their Advantages

Forging is a manufacturing process. It is used to create metal components from raw materials. It is one of the oldest metalworking techniques. It is still used today for forged components production such as forged flanges.

Forged flanges have the strength, durability, and performance needed for the oil and gas industry, as well as a range of applications. They connect pipes, valves, pumps, and other equipment in a piping system.

Here are different types of forged flanges used in the oil and gas industry:

- Weld Neck Flanges –These are the most used forged flanges in the oil and gas industry. They have a long-tapered hub that provides an excellent butt welding connection to the pipe. The advantages of weld neck flanges include their high durability and ability to withstand high pressure and temperature.

- Slip-on Flanges – These flanges have a flat face and are designed to slip over the end of a pipe. They are easy to install and are suitable for low-pressure applications. The advantage of slip-on flanges is their ease of installation.

- Blind Flanges – These are solid discs used to close off the ends of pipes, valves, or equipment. Blind flangesare useful when a section of piping needs to be closed off temporarily. The advantages of blind flanges include their ability to withstand high pressure and their ability to prevent leaks in the piping system.

- Threaded Flanges – These flanges have internal threads that allow them to be screwed onto a pipe. Threaded flanges are suitable for low-pressure applications and are easy to install. The advantages of threaded flanges include their ease of installation and the ability to easily remove them for maintenance.

- Socket Weld Flanges – These flanges are like slip-on flanges, but they have a socket weld connection instead of a slip-on connection. Socket weld flanges are suitable for high-pressure applications and are easy to install. The advantages of socket weld flanges include their high durability and ability to withstand high pressure.

- Lap Joint Flanges –These flanges consist of two parts: a stub end and a loose backing flange. The stub end is welded to the pipe, and the backing flange is free to rotate around the stub end. Lap joint flanges are suitable for applications where alignment is critical. The advantages of lap joint flanges include their ability to rotate around the stub end, which makes them easy to align.

Why Quality Matters in Forged Flanges Manufacturing

Quality matters in forged flanges manufacturing to meet or exceed industry standards. Because the components are used in the oil and gas industry, they must be able to handle high temperatures and pressure. They also need corrosion resistance properties. In the oil and gas industry, they will encounter corrosive materials and are often used on offshore drilling platforms.

What Are the Benefits of Working with a Professional Manufacturer?

Working with a professional forged flanges manufacturer has several benefits, including:

- High-Quality Forged Flanges:Our experienced engineers have the expertise, equipment, and technology to produce high-quality forged flanges that meet or exceed industry standards. We also use advanced forged production methods and quality control processes to ensure reliable and durable products.

- Customization:We also offer custom forged services to meet your specific needs and application. We can produce flanges in various sizes, shapes, and materials, according to the requirements of the project.

- Technical Support:Forged Components has a team of expert engineers. They can help with product selection, design, installation, and maintenance.

- Timely Delivery:We also have the resources and logistics in place to ensure timely delivery. We work closely with their customers to coordinate shipping and delivery schedules to minimize downtime and delays.

Do you need a reliable manufacturer of forged components that can meet your specific needs? Look no further than our experienced team at (281) 441-4088. We offer custom designs and high-quality services to make your project come to life. Need a quote? Contact us online and get it fast.