What Are the Benefits of Using Long Weld Neck Flanges?

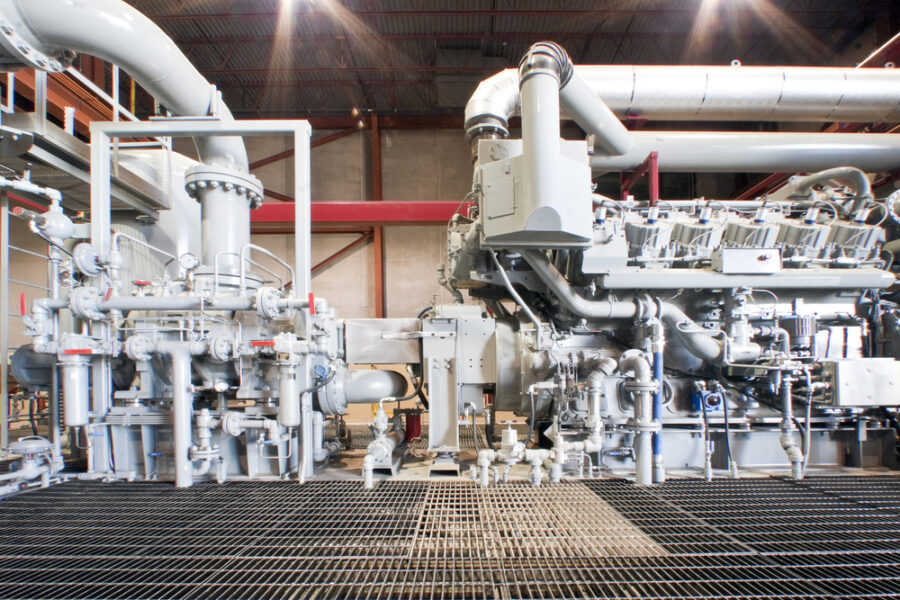

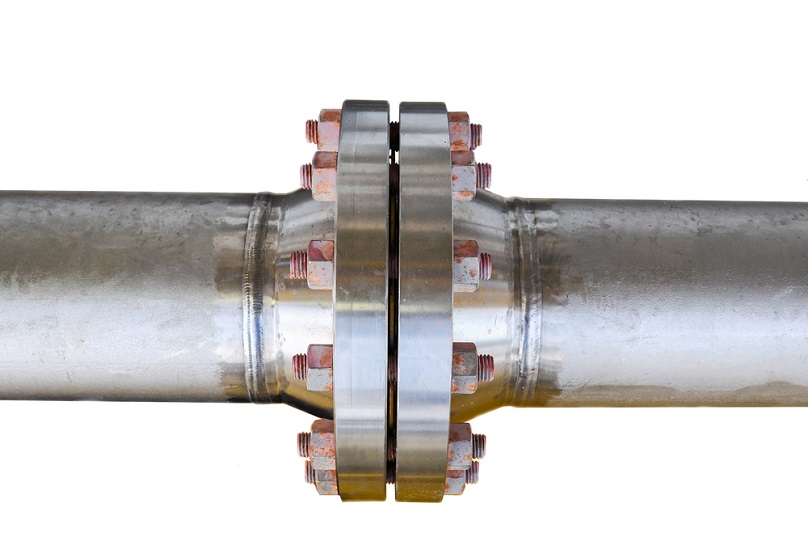

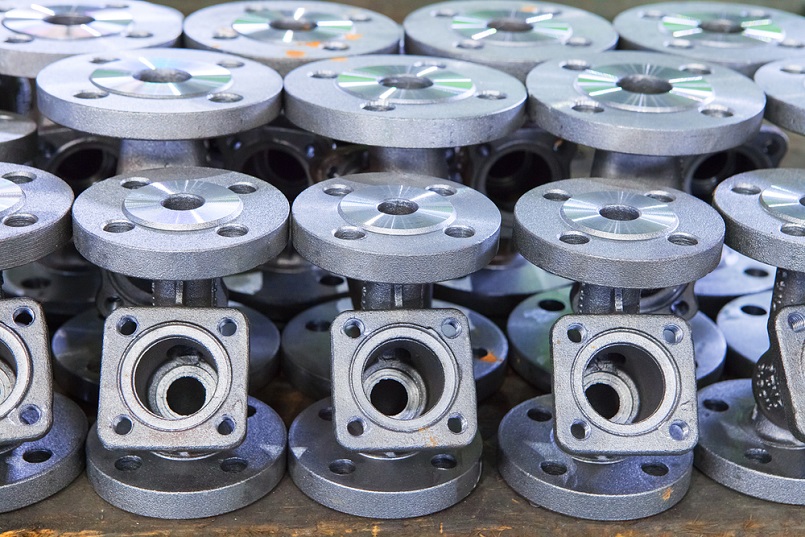

Long weld neck flanges are common specialized connections used in the energy, oil, and petrochemical industries among others. They are typically found in complex pipeline systems serving multi-level buildings and refineries. But why are they considered to be the perfect pressure vessel connections for these pipeline systems? Here are a few of the reasons: Extremely Strong and Reliable Long weld …